Testing makes the difference

Testing makes the difference

Test Camp Intralogistics will open its doors for the fourth time at Messe Dortmund on 10 and 11 April 2024, with over 100 innovations on display, covering around 10,000m2. We asked Thilo Jörgl, event manager, to explain its motto, “Testing makes the difference”, and provide insights into this logistics event.

It’s almost time for Test Camp Intralogistics, the test event with an accompanying congress. Test driving forklifts, working with exoskeletons, operating all kinds of warehouse technology yourself, interacting with driverless transport vehicles and logistics robots, trying out software… at Test Camp Intralogistics, everything revolves around the hands-on testing of selected innovations and new developments in warehouse and material flow technology.

“Testing makes the Difference” is the motto of Test Camp Intralogistics. What makes the event different from other events – trade fairs, for instance?

Firstly, it’s definitely not a trade fair. We have intentionally committed ourselves to not being a trade fair. Trade fairs are big and crowded, everyone from the industry can exhibit. Intensive discussions are often neglected, and it is usually not possible to test exhibited products.

Please don’t misunderstand us; we love trade fairs and enjoy attending events at home and abroad. Nevertheless, it was important to us to establish Test Camp Intralogistics as a different kind of event: smaller, more personal, more direct. Class instead of mass; an event with a conference at which only selected innovations are presented, not products en masse – and not just to look at, but to try out. This is regardless of whether it is a forklift truck, a software product, or something completely different.

So if – unlike a trade fair – not just anyone can exhibit at Test Camp Intralogistics, who can present their innovations?

A good mix of products and solutions is important to us. For this reason, we select our exhibitors carefully and make sure that the exhibits on show are not only innovative, but also have not been available on the market for many years. Each year, the finalists of the IFOY Award are selected having undergone a three-stage audit as part of Test Camp Intralogistics.

We also do our own research in our network and approach companies worldwide that have innovations and new products to offer, as well as being a good fit for the event. The whole package has to be attractive to visitors.

Do similar restrictions also apply to visitors? Not everyone is allowed to enter, right?

The same applies here: quality instead of quantity. Of course, we try to make this possible for everyone who wants to visit Test Camp Intralogistics. However, the number of available tickets is limited because we are not aiming for overcrowded company boxes. Rather, we want to create space for intensive discussions between manufacturers and visitors with a concrete interest in buying and investing.

In addition, our cooperation partners, some logistics initiatives, and our exhibitors invite top-level B2B guests. These are precisely those decision-makers from industry, trade, and logistics services who are not only significantly involved in the acquisition of new solutions in their companies, but also want to see these solutions live and touch, drive, and test them first hand. They also appreciate being able to do this in peace and quiet; nobody feels comfortable when 10 people are already waiting all around them to test a product.

Which industries are represented as visitors on site? Is there a general trend here?

Logistics service providers are the most strongly represented at Test Camp Intralogistics, and in this group it is mainly contract logistics providers. Due to the AGV Mesh-Up, numerous experts from automotive industry sectors are also on site. E-commerce, retail, consumer goods, beverage suppliers, mechanical engineering, chemicals, and pharmaceuticals are among the sectors represented.

Last year, Test Camp Intralogistics hosted 1,200 participants. The relatively low number of visitors means that exhibitors have the chance to talk to visitors in a relaxed atmosphere, present their products in detail, and make themselves available for on-site testing.

Many visitors are responsible for investment budgets in the three-digit million range. We offer them the opportunity to take an in-depth look at the latest innovations at the beginning of the year, laying the foundations for further discussions and contracts later on. In the meantime, there have already been some major deals that originated at Test Camp Intralogistics. This is of much greater value to the exhibitors than going home with as many leads as possible.

Are there any other points that differentiate the event from a traditional trade fair?

Test Camp Intralogistics is a holistic experience format in which selected innovations meet decision-makers willing to invest. We help to make the visit as efficient as possible for these decision-makers. At a trade fair, you are handed a list of exhibitors and have to plan your own day. With us, this is not necessary, because anyone who wants to can have the innovations presented to them at a glance as part of guided, themed highlight tours through the hall.

In addition, we try to design our areas in such a way that the visit is as varied as possible. We do this for example with special exhibition areas. The VDMA’s AGV Mesh-Up is a live test of the VDA 5050 communication interface, which is designed to ensure that mobile robots in warehouses can communicate with each other via plug-and-play technology regardless of the manufacturer. We also have an attractive conference program with half a dozen panel discussions on offer and a get-together on the first evening, which is an ideal opportunity to expand your network in the community.

The IFOY Test Days are also part of Test Camp Intralogistics. How are the Test Camp and IFOY Award connected?

The IFOY Award and the Test Camp are – to put it casually – brothers and sisters in spirit. Test Camp Intralogistics was originally created from the IFOY Award and the IFOY Test Days (which are part of the IFOY Award), but is now an independent event. As part of the IFOY Test Days, all companies and their innovations that have made it to the finals in the competition for the IFOY Award must undergo a three-stage IFOY audit.

For a long time, only the finalists themselves, our international jurors, the testers and the IFOY partners had access to this. During IFOY Test Days 2018, some of the jurors – all of them editors-in-chief of leading logistics media worldwide – invited contacts from their readership, including few logistics service providers, automotive suppliers, and DIY store managers. They were all enthusiastic about the opportunity to test the IFOY finalists themselves. So the idea was born to always admit a limited number of B2B guests – initially 50 in 2020, a few more in 2021, and by 2022 almost 1,000. Test Camp Intralogistics is now an independent event, but still offers the perfect setting for the IFOY Test Days.

Another special feature of Test Camp Intralogistics is the topic of sustainability. How can an event of this size be sustainable?

Sustainability is much more than just a buzzword. When you look at large trade fairs in particular, it is shocking to see the amount of waste they generate. Another problem in terms of sustainability is individual booth construction – in line with the motto “higher, bigger, further”, exhibitors try to compete with each other. This is not only a burden on company coffers, but also on the environment.

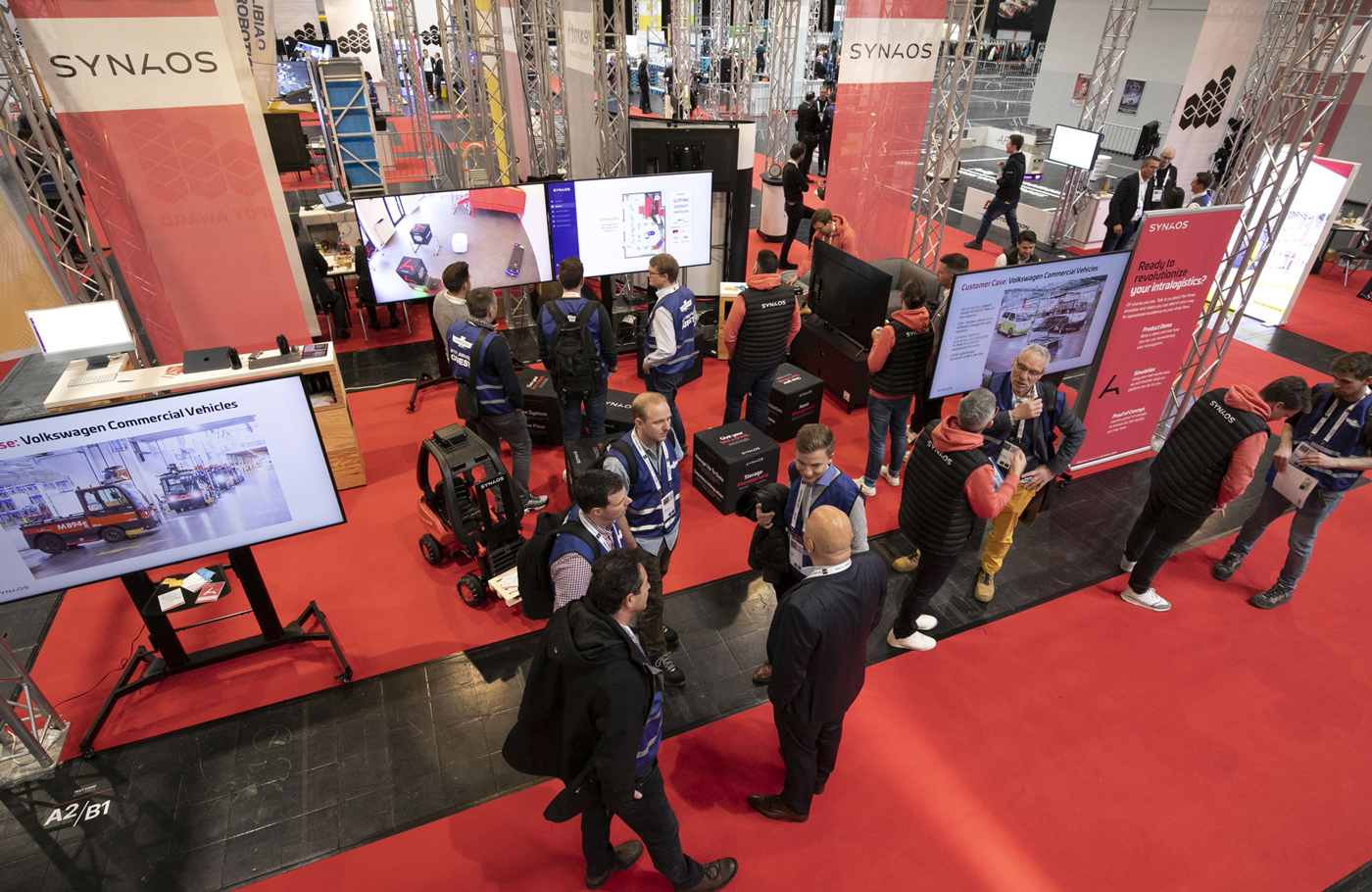

It is important to us at Test Camp that it is not about appearance, but about functionality. For this reason, we have decided not to allow individual booth construction, but to plan, set up, and dismantle the company boxes centrally in the form of modules made of aluminium trusses. The branding is also standardised, and additional branding is not necessary. We believe in “innovation instead of unnecessary decoration”.

Many of the materials we use during assembly are reusable. This applies not only to the aluminium trusses, but also to the barrier fences and the rental furniture from service providers in the vicinity of the event. The carpet we use is shredded after the camp and made into a new carpet, the central catering in the restaurant saves water and resources, and we also use green electricity.

Practically, how does on-site testing work?

As already mentioned, we take visitors on highlight tours to all exhibitors to give them an initial overview. Afterwards, each manufacturer offers individual test rides or tests and explains their innovations in detail in one-on-one discussions. All test areas are cordoned off and safety shoes are mandatory for all participants. In addition, we issue safety vests to everyone who enters the hall.

What will be the highlights of the event in 2024?

One of the key topics at Test Camp Intralogistics 2024 will be mobile robotics. As this topic is becoming increasingly important for both 3PLs and contract logistics, we are not only taking this into account with a special test area of around 2,000m2, but are also organising a separate conference as part of the camp. On the second day of the event, the main stage will be reserved exclusively for the topic of mobile robotics.

In addition to a keynote speech and panel discussions, including one on the VDA 5050 communication interface, there are also numerous specialist presentations by scientists, manufacturers, and users planned.

Published by

Focus on Transport

focusmagsa