Self-driving trucks are here!

Self-driving trucks are here!

Daimler Truck plans to introduce series-production driverless trucks in the United States by 2030. GIANENRICO GRIFFINI got a taste of things to come when he hopped aboard a Freightliner Cascadia self-driving truck on the highways around Albuquerque, New Mexico, USA.

We don’t have to wait years to see self-driving trucks on public roads. They are already a reality in the United States, with some prototypes based on the Freightliner Cascadia platform. Built by Daimler Truck North America, the Class 8 long-haul trucks, equipped with Level 4 automated driving systems, are undergoing field tests in actual operating conditions on interstate routes around Albuquerque, New Mexico.

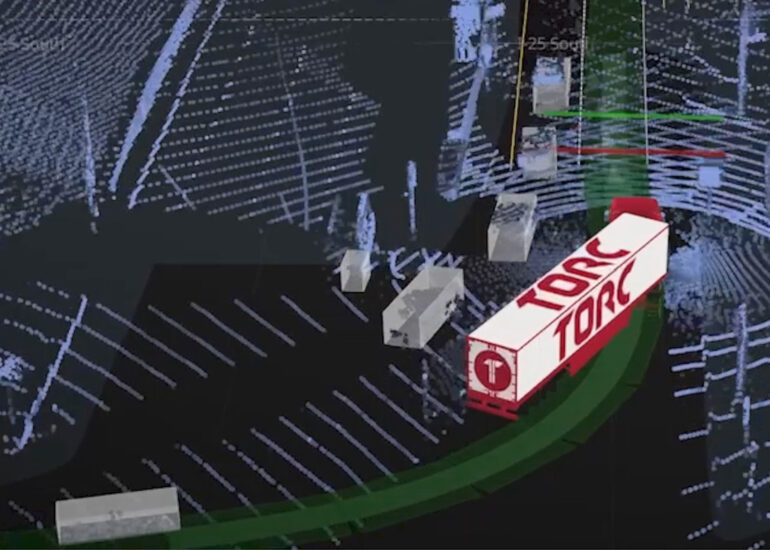

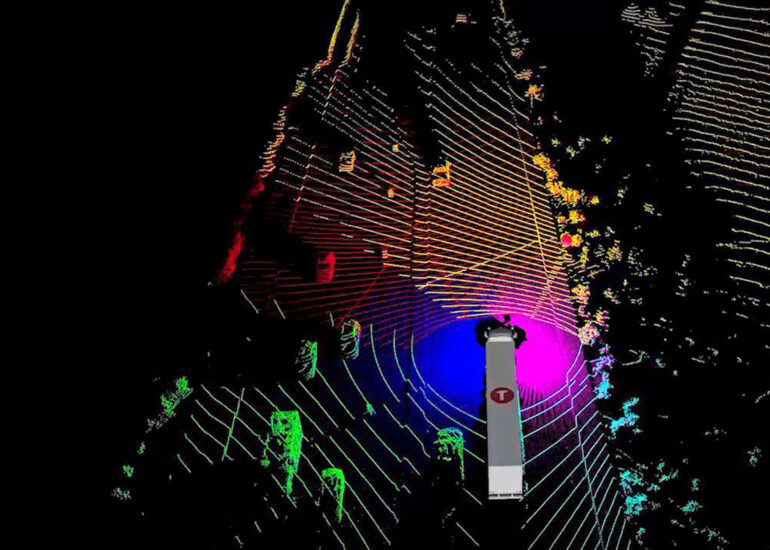

Albuquerque is the HQ of Torc Robotics, a company acquired by Daimler Truck in 2019. Torc develops the software and integrates and fuses the inputs from different sensors – such as cameras, lasers, radars, and lidars – to allow safe automatic driving on high-traffic density highways. A lidar is a device that uses a laser beam to measure the distance from an object, returning high-resolution 3D information on the surrounding environment.

On the highway at 65 mph

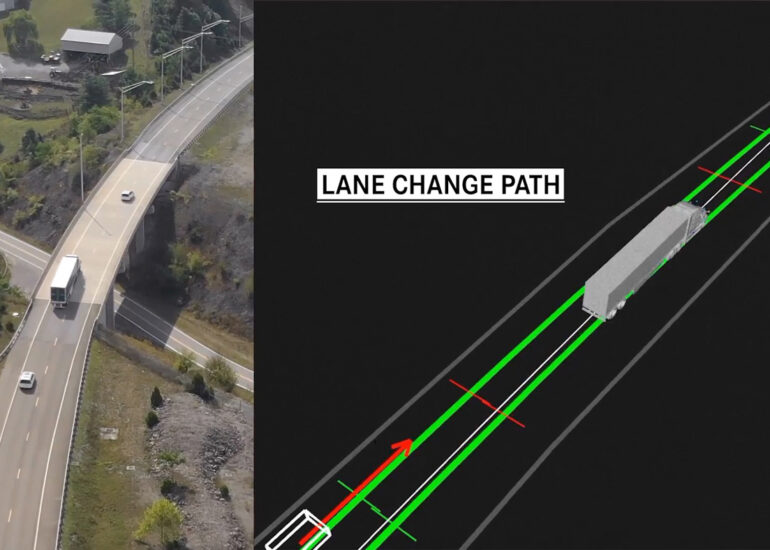

The validation tests are not held in confined areas, but on multi-lane highways. The tests are conducted using a standard tractor-semi-trailer combination of 80 000 pounds (about 36 tonnes) running at the US maximum cruising speed of 65 mph (just under 105 km/h).

For safety reasons, a human safety driver assisted by a Torc Robotics engineer is always ready to take complete control of the articulated lorry if a risky situation arises during road tests. The safety driver also has a crucial role in providing the software specialists with the feedback needed to program the onboard computer according to a prudent, safe, and fuel-conscious driving style, without hard braking and harsh accelerations.

Why the United States?

Daimler Truck’s decision to develop autonomous driving solutions first in the United States depends on multiple factors. Firstly, the US has the most branched and extensive motorway network globally, while the speed difference between trucks and cars is not as high as in the EU.

Moreover, US highways represent a more structured environment than an urban setting. There are lanes headed in the same direction, and it’s easier to predict where cars are supposed to be going. In this environment, the Freightliner Cascadia can handle most traffic situations: lane merges, merging into traffic from a ramp, changing lanes, and slowing down or speeding up.

The US legislative framework is also favourable, since the only counterpart to the truck manufacturers is the US Department of Transportation (DoT), which is proactive in facilitating the introduction of technical innovations.

Furthermore, self-driving 18-wheelers respond to clear business cases and market needs, such as a continuous increase in freight demand transported by road (a 30% increase is expected by 2030) and a growing shortage of heavy vehicle drivers. According to American Trucking Association (ATA) estimates, unfilled driver jobs slid to just under 78 000 units in 2022, down about 4% from more than 81 000 in 2021. This is still a considerable number, which according to ATA forecasts is bound to skyrocket to more than 160 000 units by 2031.

The driver shortage is due, among other reasons, to a significant number of retirements and the industry’s failure to recruit more women, who account for only 8% of the overall workforce.

Hub-to-hub application

In developing autonomous driving solutions for the US, Daimler Truck has focused on a specific business case: connecting one logistics centre to another (hub-to-hub) along a motorway. When the truck arrives at the destination hub, a professional truck driver takes it to the final unloading point. In March 2022, Torc Robotics created a special advisory board known as the TAAC (Torc Autonomous Advisory Council) with leading companies in the sector, such as Schneider, Covenant Logistics, Penske Truck Leasing, and Ryder System.

The TAAC’s aim is to foster collaboration and better understand the challenges faced by logistic companies. It comprises key freight industry players who will provide strategic guidance to Torc as it integrates with the freight network and tackles challenges beyond highway driving. The goal is to introduce Level 4 series vehicles by 2030, and the platform used to develop autonomous driving solutions is the Freightliner Cascadia.

With an approximately 85 000 to 100 000-unit annual sales volume in a normal market situation, the Cascadia is the best-selling Class 8 tractor in the US. In 2022, Freightliner had a 42% market share in the heavy-duty segment, reaching a full-year total sales volume of more than 254 000 vehicles (compared with about 222 000 units in 2021).

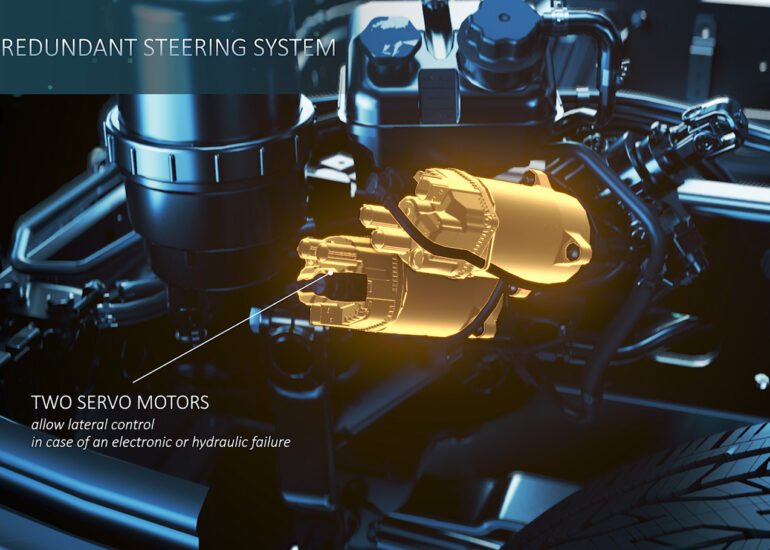

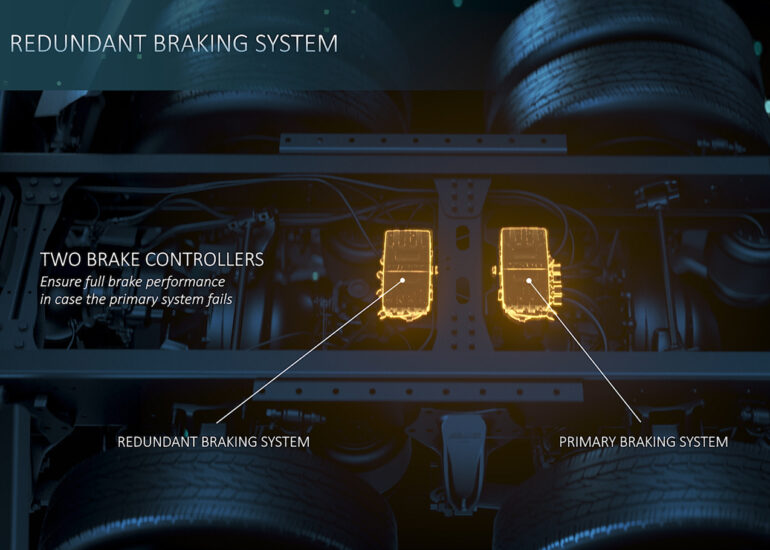

For safety reasons, the experimental Cascadia has many independent systems (if the first one fails, the second one takes full control). For instance, there are two independent systems for the foundation brakes, steering actuation, vehicle data transmission network (CAN-Bus), and parking brake.

The primary and secondary Electronic Braking System (EBS) Controllers, in particular, offer precise and reliable controls to decelerate the truck and trailer. Should the primary EBS encounter any critical faults, the secondary EBS will take over to execute a safety procedure called Minimal Risk Manoeuvre (MRM), whereby two servo motors electronically assist the steering gear. Should either of the servo motors experience a fault, the second unit takes over completely to provide the required steering commands to execute the MRM procedure.

Torc engineers have also fully addressed cybersecurity concerns – which are of paramount importance in developing autonomous driving solutions – via anti-hacker protection.

Finally, although Daimler Truck North America has not disclosed any figures on forecasted autonomous driving vehicle sales, it does expect that self-driving vehicles will manage 6% of freight volume by the end of this decade.

Published by

Focus on Transport

focusmagsa