Iveco goes green

Iveco goes green

FPT Industrial, the global powertrain brand of the Iveco Group, has inaugurated its new ePowertrain plant in Turin – and we were there!

The opening of the facility is extremely significant because it’s the world’s first carbon-neutral Iveco Group plant. Measuring 15 000 m2, the plant is dedicated to the production of the brand’s electric range, including electric axles, electric central drives, and battery packs for light commercial vehicles, minibuses, and buses. At full capacity, it will produce over 20 000 electric axles and over 20 000 battery packs per year for LCVs, minibuses, and buses. The plant is ultimately expected to employ about 200 people.

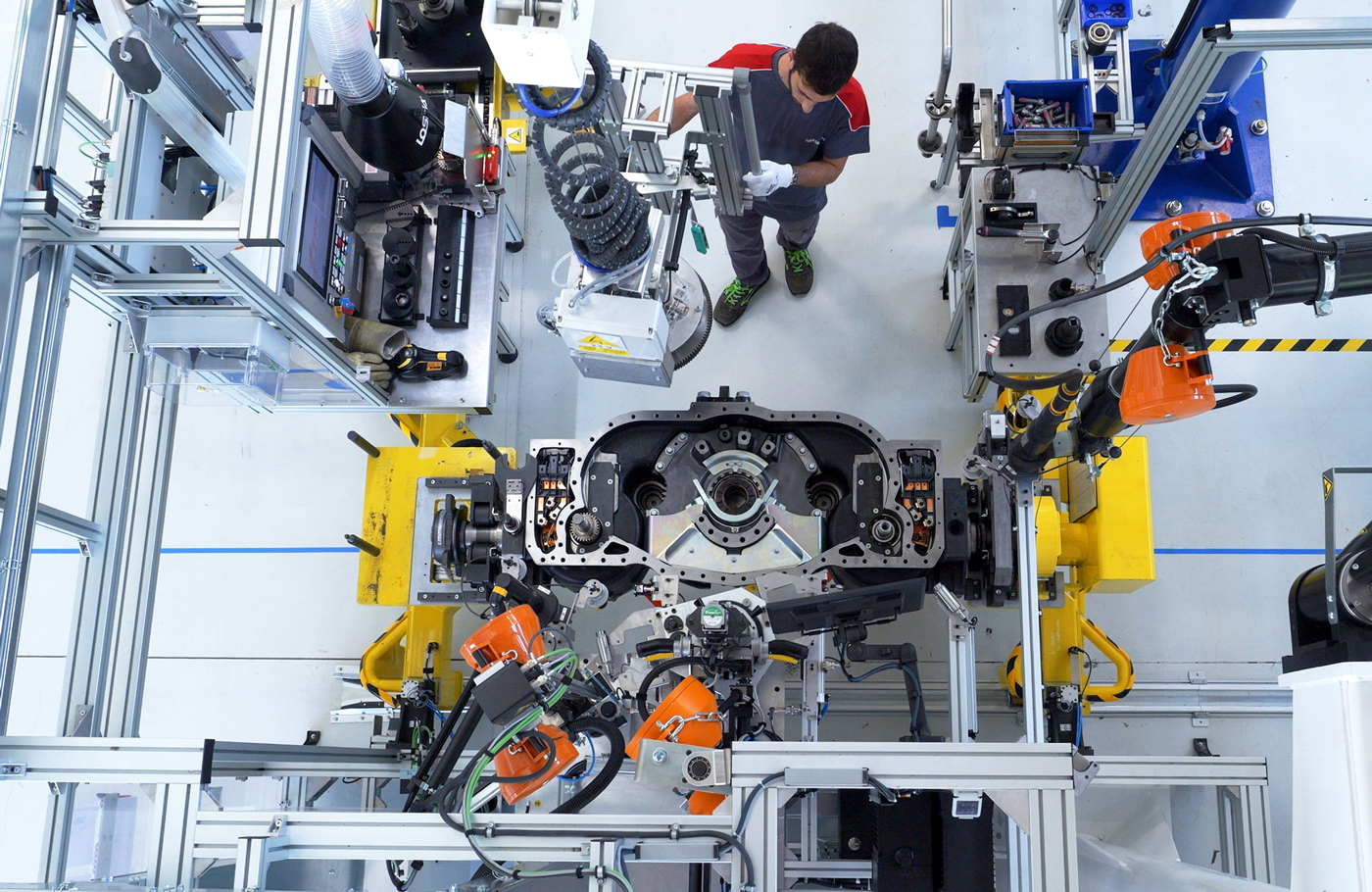

We toured the facility, which looks a bit more like a hospital than a factory; spotlessly clean, the plant has implemented numerous health and safety measures to protect the workers (who are, after all, dealing with high voltages).

Next-generation technologies adopted include augmented and virtual reality (which reduce the design time for production lines by simulating operational outcomes before physical installation); 3D printing and “Smart Observer” systems based on intelligent sensors; 3D scanners for metrology-grade measurements; 3D reality simulators; and cooperative robots. These robots, together with Automated Guided Vehicles, greatly improve ergonomics and safety, making the operators’ jobs easier and less stressful.

Below: Sylvain Blaise, president of the Powertrain Business Unit; Domenico Nucera, president of the Bus Business Unit; Luca Sra, president of the Truck Business Unit; and Annalisa Stupenengo, chief operations officer of the Iveco Group, participated in a panel discussion at the official opening of the plant.

The state-of-the-art factory has implemented numerous health and safety measures to protect the workers. No heavy lifting is required, for instance.

Cloud quality checks allow instant detection of problems, while end-of-line checks certify the conformity of the product in terms of configuration, performance, and safety.

On the HCV electric axle line, a station with light signals supports the operator by clearly indicating which component is to be selected and where to mount it, thus helping achieve the zero-error target. On the battery assembly line, dielectric carpets protect operators against possible electric dispersions, while thermal imaging cameras automatically measure battery temperatures, immediately reporting any deviation from the norm.

Iveco Group representatives addressing the dignitaries at the official opening included Sylvain Blaise, president of the Powertrain Business Unit; Domenico Nucera, president of the Bus Business Unit; Luca Sra, president of the Truck Business Unit; and Annalisa Stupenengo, chief operations officer of the Iveco Group.

“As key energy transition players in all on-highway and off-highway sectors, we are pioneering new clean energy propulsion systems and we are fully committed to reaching the ‘net zero carbon’ goal by 2040,” said Blaise. “Our new ePowertrain plant is a fundamental step in this process. The electrified products we manufacture here will accelerate decarbonisation in the transport sector, providing our partners and customers with cutting-edge solutions for their future product line-ups.”

Below: Members of the International Truck of the Year jury are joined by Gerrit Marx, CEO of the Iveco Group.

Alessandro Sezza, plant manager at the Turin site, explained that people are the key to the plant’s success. “Our team is called to acquire a new mindset to approach the new challenges of e-mobility and new skills to relate to the Industry 4.0 environment. It’s change management,” he said.

“At the Tech Academy, we prepare our people for a completely new process, where it is fundamental to manage the information flows provided by robots and automated tools. But we also teach the soft skills they need: with a tailored programme called ‘In trasformazione’, we prepare our people to face a complex and fluid scenario.”

The new production site uses energy exclusively derived from renewable sources. In addition, the plant generates energy with solar panels installed on the façade and with innovative technologies, such as a “mini-wind tower” and a “smart flower”.

The plant is also home to the Iveco Group Sustainability Garden, a 6 000-m2 internal space planted with 100 drought-resilient plants of native species with great CO2 absorption capacity. A pedestrian path has also been created with recycled pallets.

Published by

Focus on Transport

focusmagsa