Dust contamination and component failure: a clear cause-and-effect correlation

Dust contamination and component failure: a clear cause-and-effect correlation

The road transport industry can be a high dust environment that requires regular monitoring of all machine components to identify possible threats or risks before they negatively affect equipment.

Recently, the condition monitoring team from WearCheck tested an oil sample from a client in the road transport industry. Shesby Chabaya, WearCheck Zimbabwe operations HOD, outlines the findings and lessons learnt with regards to the effects of dust contamination on machine health, as well as how these lessons can be utilised to remodel the oil sampling regime for greater success.

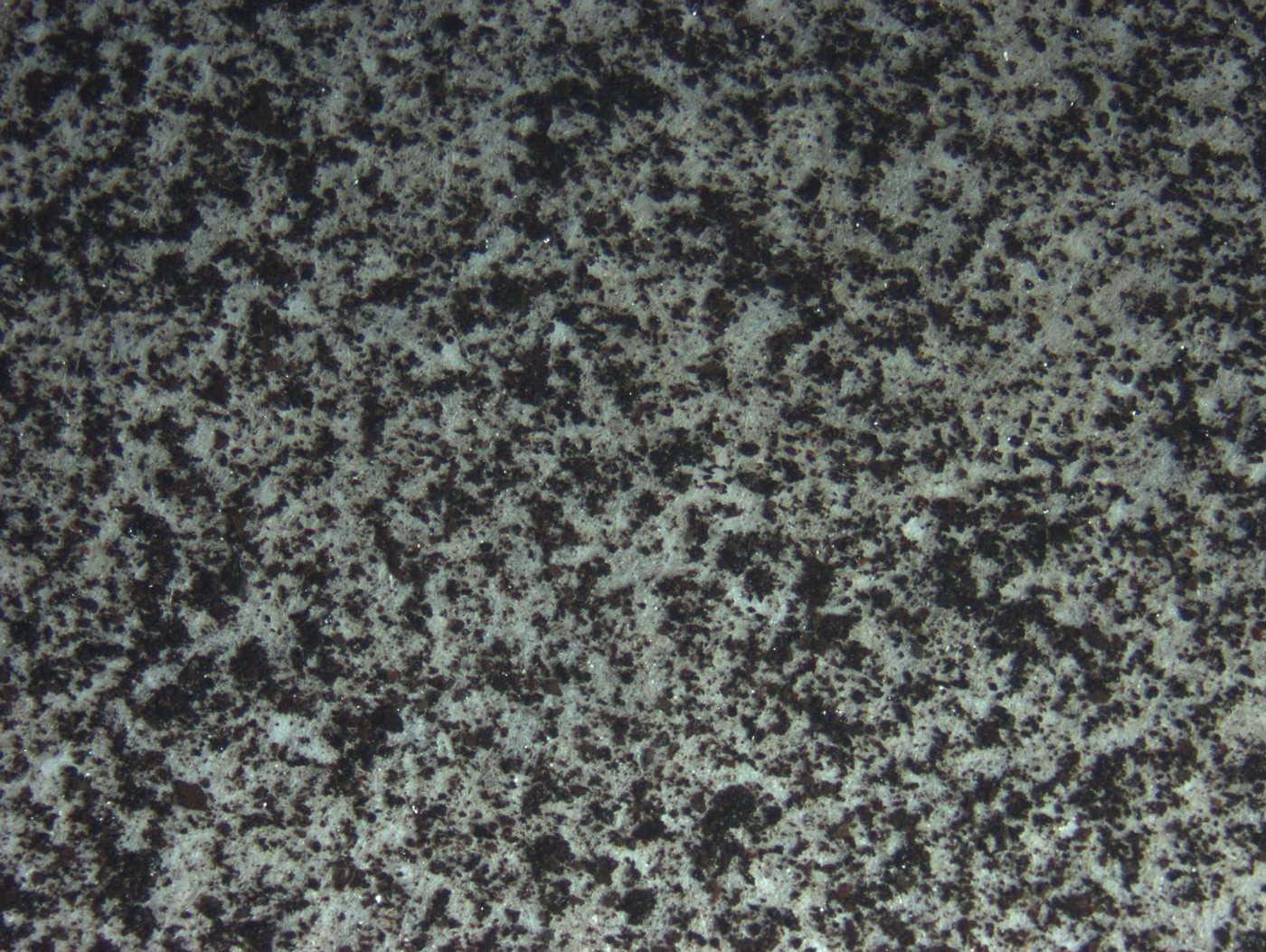

According to Chabaya, laboratory findings at the 100,000km service revealed these results: iron 639 parts per million (ppm), chromium 21ppm, nickel 18ppm, copper 147ppm, lead 180ppm, silicon 156ppm, and particle quantifier reaching 12 995MgFe/L. The microscopic particle examination revealed the image below:

“Customer feedback indicated that the engine failed shortly after the service was done. The root cause of dust ingress was discovered to be a torn air induction hose. The tear was not easily visible with the naked eye, as it was located on the inner side of the air induction hose close to the engine block,” Chabaya says.

An evaluation found that the tear on the air induction hose resulted in dust bypassing the air filtration system and being sucked directly into the engine, thus accelerating the rate of component wear.

Chabaya notes that the road transport industry involves vehicles being driven in dusty environments, and any opening on the engine components will result in severe contamination, posing a significant risk of component failure.

“The torn air induction hose is the root cause of dust ingress, and the effect is severe wear (dust being the catalyst) and consequent engine failure. When an air induction pipe cracks after the air filter, dust enters the air intake manifold and finds its way into the engine. The dust mixes with lubricating oil and is carried through the engine via the lubrication system, acting like a “grinding paste” and wearing out components. The engine may fail to last longer than 1,000km, depending on the intensity of dust ingress,” he elaborates.

“Unfortunately, this engine had not been sampled since the machine was commissioned. Only a single sample came through at 50,000km,” Chabaya continues. He adds that had the machine been sampled every 10,000km, the problem could possibly have been picked up earlier and rectified, avoiding a catastrophic failure.

WearCheck’s scientific oil sampling techniques and other condition monitoring services have helped many fleet operators and other businesses to avoid major vehicle breakdowns and save money on repairs.

“A more regular and systematic oil sampling regime following set oil sampling intervals results in huge cost savings and increased equipment reliability,” Chabaya emphasises. “With a properly set up condition monitoring programme in place, specific parts can be ordered and maintenance can be planned, thus avoiding interruption to business.”

Published by

Focus on Transport

focusmagsa