“Speed is part of innovation”

“Speed is part of innovation”

What do intralogistics manufacturers have to improve, what role do start-ups play, and how has the International Intralogistics and Forklift Truck of the Year (IFOY) Award developed? THILO JÖRGL talks to Gordon Riske, chairman of the board of the Verband Deutscher Maschinen- und Anlagenbau (VDMA) Material Handling and Intralogistics Association.

Gordon Riske – who is also CEO of the Kion Group – attended the Ifoy Test Days for the very first time this year. His visit presented us with the ideal opportunity to ask him some pressing questions.

You started at the VDMA in February 2020, shortly before the lockdown. What is your conclusion after one year?

Gordon Riske: The Covid-19 pandemic and Brexit were, of course, the all-dominant topics last year, also at the VDMA. But there were also other important topics – such as the extension of the transition engine and the VDA 5050 interface, a real milestone in the intralogistics sector. All in all, it was a very active year. And at the VDMA, we can be very satisfied with the results.

What were the major challenges for the intralogistics providers during the pandemic?

On the one hand, there were a lot of uncertainties: material shortages, the instability of the production systems, getting service people out to the customers – to name a few. Installing a new warehouse was sometimes impossible. But on the other hand, the demand for new, digital solutions started to grow in the second half of 2020. There was much more pressure on the companies to be competitive. In the spring of 2020, the pandemic hit us hard. But by the fourth quarter of 2020, we were dealing with it.

What will change for intralogistics?

The crisis has probably given us a boost in areas like digitalisation, automation and sustainability. There are customers who ask us now: How many human touch points do you have in your system on an average day? And how can you reduce them? This topic will stay with us. Electrification also plays an important role. At the Kion Group, for example, last year more than 87% of the delivered products were electrically driven. Ten years ago, that was very different.

Industry and retail face three major problems: uncertain demand situations, insecure supply chains and labour shortages. How can intralogistics providers help them?

Indeed, the labour shortage is a challenge. Look at the IFOY Award: You see far fewer forklifts driven by humans than in previous years. And you see many more AGVs or warehouse devices without a driver. The autonomous, digitally driven product base will be more important in the future. That helps our customers in terms of efficiency and labour shortage.

In which areas do intralogistics providers need to improve?

Everyone understands that digitisation is important. But there are other areas where understanding and readiness are not as embedded as they should be. For example, sustainability is not just a task for society: Every company can and must do something. We really need to develop long-term strategies. Another example is the topic of speed …

What do you mean?

German companies in particular want to plan everything and tend to overengineer things. And sometimes they are afraid of just getting started. If you look at Asian competitors, the willingness to accept mistakes is much greater. But the speed of getting things done is also much greater. Speed is part of innovation. Digitalisation has made things more transparent. If we in Germany are too slow and not willing to take a risk, we will fall behind the Asian competition.

What role do start-ups play in intralogistics?

They play an extremely important, positive role. Most of the time, it’s young people who are willing to take a certain risk. Well, sometimes there’s an investor behind it to make it financially possible.

But that’s not always the case. However, we see innovative ideas in start-ups that perhaps wouldn’t be done in the same way in larger companies. That helps both sides. Because larger companies have access to the market and customers, and of course the necessary production experience. The established industry is important for these young entrepreneurs to turn their ideas into reality.

Will start-ups take business away from some old corporates?

Yes, some might. I still believe in the philosophy: “Innovation over a long time makes the cake bigger.” If there is too much discussion about how to get a bigger piece of the small cake, I would rather be on the side of making the cake bigger for everyone.

Do you see any disruptive start-ups in the market that could position them with a platform between the customer and the traditional companies?

We see that all the time. Look at topics like software, data monitoring or fleet management. Where the entry barriers are not so high, a start-up can make a big difference with a relatively small input. But the scale does matter! A service network that helps the customer in the EU, the US or globally is an important advantage in the business.

The VDMA is the sponsor of the IFOY Award. Why did you decide to visit the IFOY Test Days and the Test Camp Intralogistics and what impression did you get?

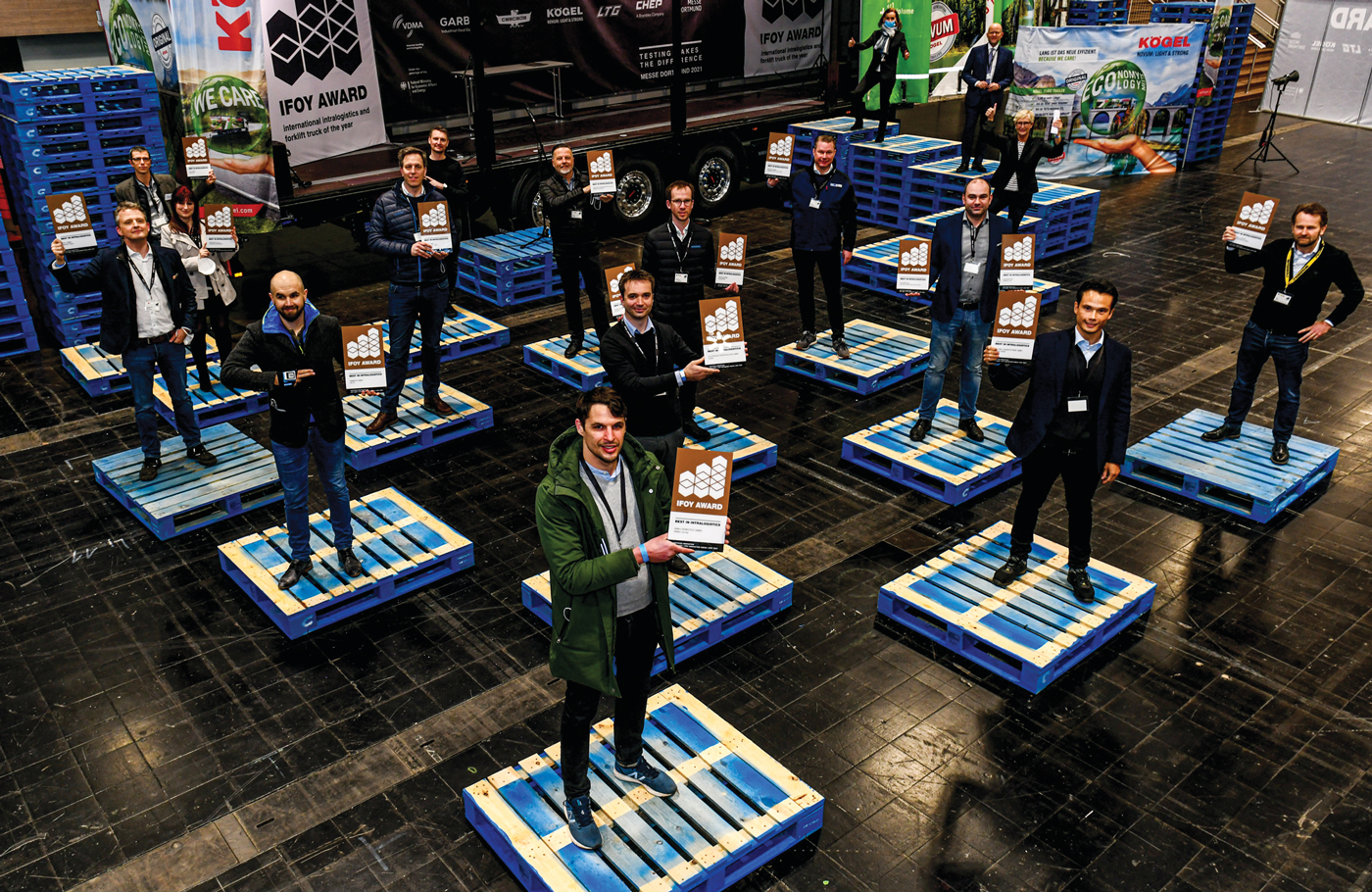

Apart from the AGV Mesh-up, I saw a great diverse set of 17 products and solutions from 14 different companies. That is one of the largest presentations we have had so far. The IFOY Award has continued to evolve – even in the pandemic.

What are the VDMA’s goals as the sponsor of the world’s largest intralogistics award?

The VDMA stands for machines and the expertise of the industry. Every industry needs showcases and platforms, where companies can present the best of the industry, show the development of innovations and take that message out to a greater public. One of the most important things the VDMA can do is to look for a platform for innovation, where companies and individuals are honoured for developing outstanding products or solutions. And the IFOY Award is such a platform.

What do you think about the development of the IFOY Award?

It has developed very nicely over the years. In 2013, you saw a lot of forklifts. Now we see a lot of intralogistics devices, software and AGVs. The IFOY Award has been very much in line with the technical development of our industry and its markets. It has an international professional jury, and the worldwide online reach is more than 800 million plus 3 000 articles per year. It is a broad message that is sent out globally.

Part of the Test Camp Intralogistics 2021 is the AGV Mesh-Up initiated by the VDMA. What is shown at the first live test of the VDA 5050 interface?

To inexperienced observers, it might not be very clear. All they see is a bunch of AGVs running around in a test area with music playing in the background. But think about it: These AGVs are running by themselves, they have sensors, cameras and tracking systems. Sometimes they get close – but they never bump into each other. The AGVs from all the different manufacturers are running under one common interface – the VDA 5050. The interface allows interoperability between different devices from different companies on one system. From a customer´s point of view, that means: I have the choice of different suppliers for products, because the devices can communicate with each other via one interface. What we are seeing here is a world première.

How important is the VDA 5050 interface for suppliers in intralogistics?

New products take off once they reach cost, competitiveness and scalability. A common interface provides scalability. It is just like years ago with 2G, 3G, 4G and now 5G. Without that standard, it would be impossible for us to communicate with our smartphones the way we do now. If you think of the AGV as a smart device going forward with one communication standard, that will bring costs down, increase reliability and give the customer a choice. The standard will help the industry to grow.

Will the VDA 5050 be successful outside Europe?

If we are fast enough and make it happen, yes. It is certainly the aim to have the VDA 5050 as a global standard, just as the VDI or the ISO standards. We are doing pioneering work here that has the potential for global reach.

Which technical trends in intralogistics will become important in the coming years?

We will see a bigger component of software, of high-speed sensors and automation. More of our future products will run autonomously. All the preparation work to enable that technology will be the ongoing trend in the coming years.

Published by

Focus on Transport

focusmagsa