Like muscles in the body

A vehicle’s transmission works hard and can take a beating from inexperienced drivers, often resulting in it needing to be reconditioned or rebuilt. WILLIAM GEORGE finds out what vehicle operators should bear in mind when having this done by an aftermarket workshop.

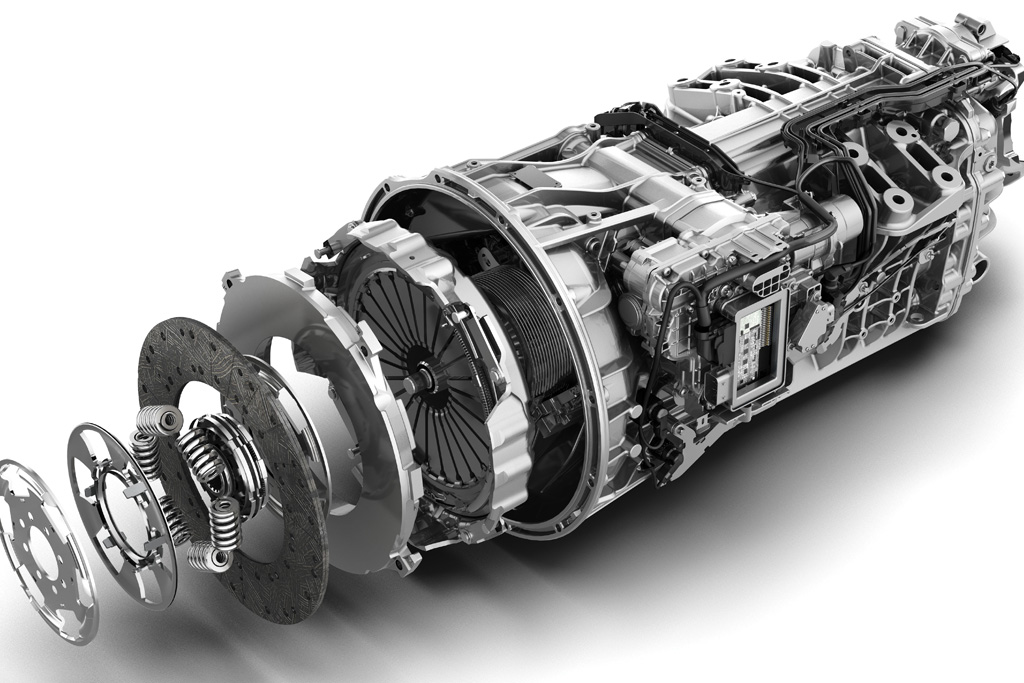

The primary function of a transmission, or gearbox, is to transmit power from the engine to the driving wheels – much like muscles in a human body that transmit energy to our limbs. Another function is to reduce high engine speed to the slower wheel speed, while multiplying torque in the process.

Common transmission failures

Transmissions wear down with time, mainly because of the friction and heat around the moving parts. Abnormal problems such as oil leaks, overheating, noise levels, no response or taking longer than usual to shift gears, are clear signs that a transmission may need to be checked.

Additionally, regular scheduled maintenance ensures that a fault may be rectified before damage is caused. It is always advisable to adhere to scheduled maintenance

and servicing, or to consult an expert or the original equipment manufacturer (OEM) in the case of symptoms of failure.

Keeping a transmission in good shape

FX Laubscher, head of technical services at ZF South Africa, recommends using the information that is stored in the control unit of a transmission.

“A one-size-fits-all kit does not exist for transmissions. Failure of one subsystem in the drivetrain can result in consequential damage to another system (of which the transmission can be one).”

There are many ways to look after a transmission, some of which involve taking care of components such as the engine, clutch and others parts of the vehicle.

Boeta Kotze, national technical manager at Rex Diff and Gearbox (RDG), says: “A transmission repair is usually a major repair and not a simple quick fix. A complete assessment has to be made when repairing the transmission.”

Laubscher shares this sentiment. He says: “By evaluating the parts individually and understanding the interdependence of different subsystems on each other, the root cause can usually be determined.”

Laubscher offers some tips for transmission care:

• Each transmission type has a list of recommended service intervals based on the lubricant used.

• Ensuring that the transmission is serviced as per the schedule will fully extend the life of the transmission.

• Through the electronic integration of mechanical transmissions, some functionality is constantly measured. Once a fault code is logged related to the transmission (or any other subsystem for that matter), it is important to have the fault investigated to ensure that consequential damage is limited.

Servicing vehicle transmissions

General servicing of the transmission entails cleaning up the oil pan and removing the filter and replacing it with a new one. This also involves draining the oil and refilling it with the specific transmission fluid.

RDG uses an automatic transmission valve body machine, which is used to test transmission valve bodies before installing them into the vehicles.

“This is the latest diagnostic equipment, which is used by our skilled technicians who have undergone training at different OEMs, both here in South Africa and overseas.

“It is essential that the transmission oil gets changed in accordance with the OEM service intervals. Furthermore, it is imperative that the correct specification (viscosity) oil is used that conforms to the OEM specifications,” Kotze continues.

Laubscher warns that maintenance-related failures are the cause of most failures and can be avoided by adhering to the service schedule of the OEM.

“Ensure the correct oil levels are maintained through regular checks. A daily trip inspection could assist the operator to ensure any abnormality around the transmission is reported before it causes a failure,” Laubscher concludes.

Published by

Focus on Transport

focusmagsa