Innovation and sustainability in action

Innovation and sustainability in action

While UD Trucks may be a company with a long legacy and a fascinating history, it is obsessed with two decidedly contemporary issues, namely innovation and sustainability, as STEFAN PERTZ* and CHARLEEN CLARKE discover on a trip to Japan.

Anyone wanting to understand UD Trucks, its heritage, products, and culture, would be well advised to visit the UD Experience Center, which is located inside the premises of the UD headquarters and main plant in Ageo, Japan.

While there, it’s possible to learn all about the development of the company’s first-ever truck back in 1939. It was called the LD1, and it had a 3.5-tonne payload. The company’s goal for the truck was for it to be reliable – which was a major challenge at the time, thanks to the country’s rugged terrain. While Mount Fuji – Japan’s highest peak at 3,776m – may be the country’s most famous mountain, there are many more. In fact, about 73% of Japan’s land area is covered by mountains. This was more than trucks could handle at the time; they were constantly breaking down.

Kenzo Adachi, the founder and president of UD Trucks, was worried that his truck might do the same. So, he embarked on a test drive… but not just any test drive: the plucky chap went on a 3,000km trip! The truck left the plant a week after it had been built and, as noted by a display in the UD Experience Center: “It felt more like an adventure that was not for the faint-hearted than an endurance test.”

The road conditions were terrible (even worse than South Africa’s), as the majority of Japan’s roads at the time were unpaved and the country was full of narrow roads and bridges barely wide enough to fit a horse and cart.

“It was only their strong will and determination that got them through, and they arrived back to the plant safe and sound after 13 gruelling days. The ND1 (the name of the engine) remained in tip-top condition right until the very end,” the display reveals. “The company had succeeded in producing a diesel truck that possessed some of the most advanced technologies that Japan, and the world, had ever seen.”

Over the years, that passion for advanced technology has remained. The world’s first commercialised radar laser collision prevention system was made available as an option in 1989, for instance. The Quon, which was launched in 2004, was the world’s first truck with the urea selective catalytic reduction (SCR) system, while in 2021, UD Trucks launched active steering (see sidebar).

BACKBONE OF DEVELOPMENT: INNOVATION ROADMAP

Fast forward to 2024, and advanced technologies remain central at UD Trucks – as does innovation.

A new truck, add-ons, or improvements to truck features do not happen at random. In order to produce the sophisticated vehicles we see today, a structured, well-executed plan is required. At UD Trucks, research and development are guided by “Fujin & Raijin, Vision 2030” – a so-called Innovation Roadmap that aims to deliver a variety of solutions for smart logistics, including fully-electric and autonomous trucks. The roadmap focuses on the key areas of automation and electromobility to address the challenges of a rapidly changing world.

Nohubiko Kishi, vice president, key account management, technology, points out that research and innovation are not the same. “Simply put, a truck is not an innovative product at its core. Trucks already exist. Hence, research and development are, in a simplistic way, working along a timeline,” he explains.

“Innovations, however, are based on a different process. For instance, here customer feedback is being heard and analysed,” he continues. “From such feedback, new technology may be created, whereby it could be unclear how this new technology could be incorporated.”

Kishi uses the example of trucks not being able to operate inside buildings, due to the emissions they produce. A propulsion system that does not emit any harmful pollutants, however, opens up potential new ways of using a truck that is able to enter a building. While the idea of a truck is not an innovation, therefore, its use can be innovative: trucks may then operate in cities at night, or inside confined spaces. In other words, technology may give way to innovative vehicle use. “This does not happen very often though. This takes place every now and then only,” Kishi says.

Customer voice can also drive innovation and improvements. For instance, the Quester has seen the addition of an AMT option after customers requested it. The addition of ESCOT to UD vehicles in Australia was motivated by the demand from the Australian market for chassis with lower weight.

“Our customers have given us feedback that they prefer the ESCOT transmission. Obviously, the idea to use this is a simple statement, but actually changing the transmission requires changes to a lot of other components built into the truck. It sounds easy, but it is not,” Kishi notes.

He adds that it is important to be able to commercialise innovations, rather than simply innovating as a vanity project.

Often, innovations are spin-offs from projects that aim to address future transportation needs. For instance, the Fujin is conceptualised as an autonomous vehicle. As such, it is already equipped with ABS, automated transmission, and other automated systems needed to manoeuvre the truck without a driver. However, what UD Trucks was lacking was an automated steering system. When the team developed the system needed for the Fujin, they realised that the same steering system could be adapted to trucks driven by a human pilot.

“We lacked such a system and through the Fujin project we found a solution we can also transfer to other trucks,” explains Kishi. Instead of using it for future trucks, it is now built into the current truck range.

EMPHASIS ON SUSTAINABILITY

While innovation is central to all activities at the company, sustainability is equally important. “Our mission is to use innovation to be more environmentally conscious, while also putting people first,” explains Jacques Michel, senior vice president, UD Trucks International Sales.

Douglas Nakano, senior vice president, technology, stresses that sustainability is about more than just producing “green” trucks. “It doesn’t help to just have the truck carbon neutral; wheel-to-well neutrality is required,” he insists.

Shinya Hasegawa, senior vice president, strategy and product line management, brand and communication, agrees. “We want to be a sustainability leader,” he stresses.

In fact, Kouji Maruyama, the company’s president, says addressing climate change is the company’s primary focus. “As a member of the Isuzu Group, UD Trucks is aiming to achieve net zero CO2 emissions by 2050 in accordance with Isuzu Environmental Vision 2050. To achieve this goal, we are taking steps to reduce CO2 emissions from our operations, particularly at the procurement and manufacturing stages.

“We are also using renewable energy sources and have introduced a new system for monitoring CO2 emissions across the entire value chain,” he writes in UD’s 2023 Sustainability Report.

For instance, the Ageo plant has been purchasing electricity derived from renewable energy sources since May 2019. By using electricity from renewables instead of non-renewable sources, the factory effectively reduced its CO2 emissions by 1,060 tonnes in 2022.

In addition, the company’s training centre, adjacent to the Ageo plant, concluded an agreement in September 2022 to purchase electricity entirely from net zero carbon sources. The Ageo factory and headquarters also replaced obsolescent lighting equipment with about 16,000 LED lights between 2020 and 2022, and reduced the total number needed by about 1,500 lights by optimising lighting layouts. This initiative will help reduce CO2 emissions and cut down on waste, since the LED lights last a comparatively longer time before needing to be replaced.

The company also installed three new energy-efficient boilers at its Ageo plant in December 2022, which are substantially reducing energy consumption. Outside Japan, UD Trucks Thailand has installed a solar power system on the rooftop of its Bangkok plant. It has the capacity to generate 1,477MW hours annually. Consequently, around 25% of all energy consumed by the facility now comes from renewables, and its CO2 emissions can be reduced by approximately 700 tonnes per year.

UD is also saving energy with heat-reflective paint. For instance, in 2022, solar heat-reflective paint was applied to the roof and exterior walls of the Gunma Parts Distribution Center, the largest of the company’s four parts distribution facilities in Japan. Consequently, the indoor temperature decreased by as much as 10.5°C during the summer. This led to a 10% reduction in annual electricity consumption, and helped the facility improve the workplace environment by keeping the average temperature below 30°C.

Now it only remains for the countries in which the trucks are sold to come to the green party. As Michel notes: “South Africa is a market with great opportunities but also some challenges. You’re burning a lot of coal in South Africa. So are we in Japan. So, we need to work upstream when it comes to energy. Ultimately, we need to be proud of what we’re doing to protect the planet.”

We suspect that this is a sentiment that applies to each and every UD staff member…

*STEFAN PERTZ is editor in chief of Asian Trucker.

STRONG IN SOUTH AFRICA

While UD dominates the tractor market in Japan (one out of every two truck tractors is a UD), the company is also extremely strong in South Africa. In fact, South Africa is the company’s largest market outside of Japan.

That’s according to Jacques Michel, senior vice president, UD Trucks International Sales, who says one of the company’s keys to success is its emphasis on service. “We have a very strong and genuine service offer, with 39 dealers in South Africa. In the event of a breakdown, we are attempting to get trucks back on the road in five hours,” he reveals.

Speaking of dealerships, he says joint UD and Isuzu dealerships won’t happen. “We don’t have multi-brand dealerships,” he stresses.

What the company will have, however, is a network of top-notch dealers. “Last year, we inaugurated a larger and more prominently located facility for UD Trucks in Cape Town. South Africa remains integral to our global business footprint, and with Cape Town being the second biggest port in the country, we have no doubt that the investment in the new establishment allows us to be well-poised in better serving our customers and the market at large,” he says.

Those dealerships will continue to receive products that are ideal for the South African market. “Ten years ago, we were designing trucks for Japan. Then, we would export those trucks,” Michel relates. “That’s all changed now. We start designing trucks for export markets from the very start.”

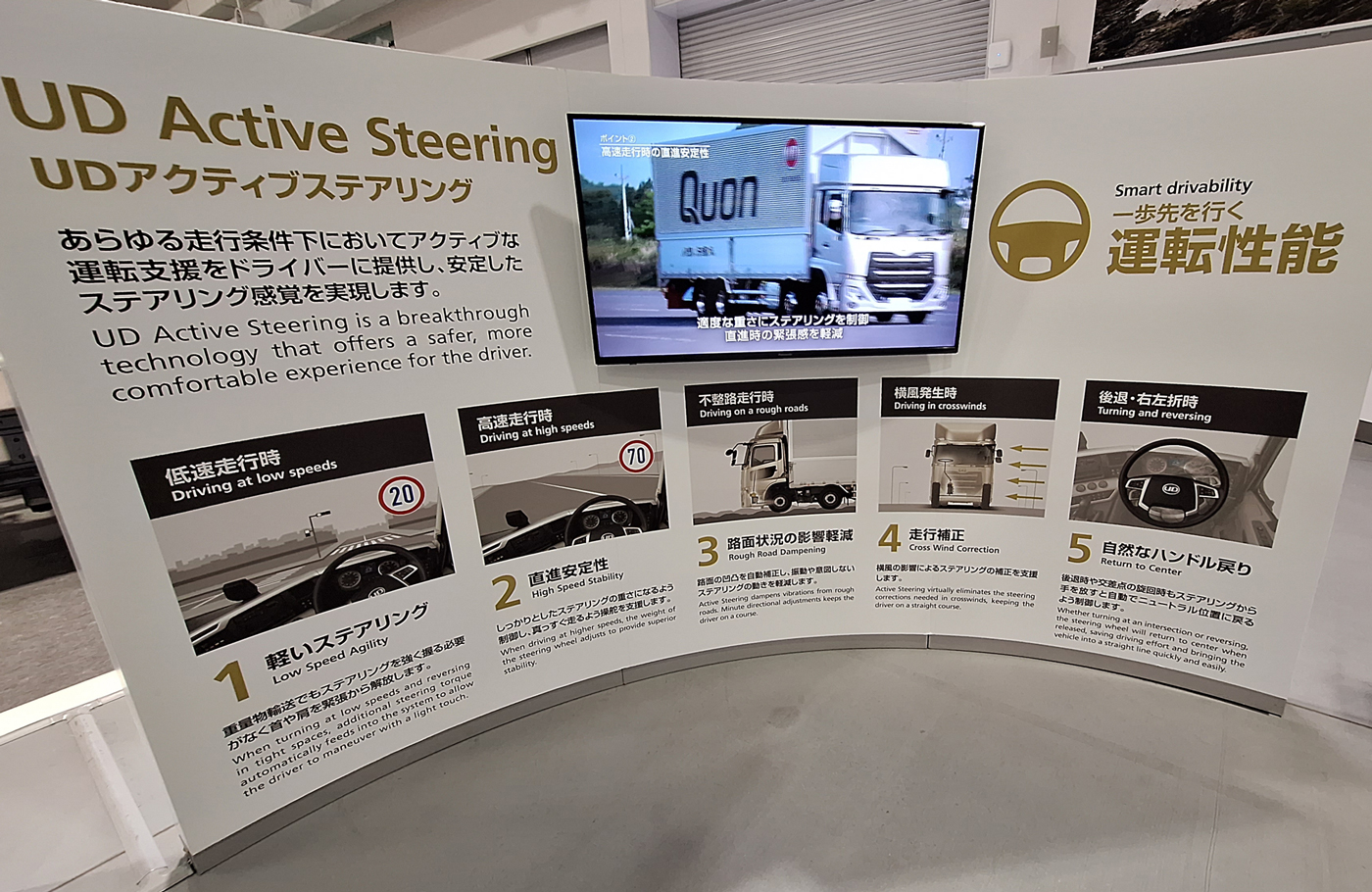

ACTIVE STEERING: WHY IS IT A BIG DEAL?

UD Active Steering features an electric motor mounted above the hydraulic steering gear to provide additional torque when necessary. The electronic control unit (ECU) mounted on the electric motor receives input 2,000 times per second from sensors throughout the truck, monitoring the driving environment and the driver’s own actions. This system control adds appropriate torque to the weight of the steering wheel, providing precise and stable steering irrespective of speed, cargo, and road conditions. The ease and precision of steering help reduce driver fatigue and make roads safer.

Five benefits of UD Active Steering:

- Low-Speed Agility

When turning at low speeds and reversing in tight spaces, additional steering torque automatically feeds into the system to allow the driver to manoeuvre with a light touch.

- High-Speed Stability

When driving at higher speeds, the weight of the steering wheel adjusts to provide superior stability.

- Rough Road Dampening

Dampens vibrations from rough roads. Minute directional adjustments keep the driver on course.

- Cross Wind Correction

Virtually eliminates steering corrections needed in crosswinds, keeping the driver on a straight course.

- Return to Centre

Whether turning or reversing, the steering wheel will return to the centre when released, saving driving effort and bringing the vehicle into a straight line quickly and easily.

Published by

Focus on Transport

focusmagsa