IAA smashes records

IAA smashes records

The 2024 IAA Transportation, which took place from 17 to 22 September in Hanover, Germany, grew by 10% from the previous edition. This year it attracted around 145,000 visitors, and CHARLEEN CLARKE was one of them.

This year IAA smashed a number of records. There were nearly 1,700 exhibitors from 41 countries, a 21% increase compared to 2022. International participation soared to a record 72%, and over 145 world and European premieres took place.

Needless to say, VDA President Hildegard Müller was rather happy with the show. “The IAA Transportation has powerfully demonstrated that our industry is actively driving the shift toward climate-neutral solutions through investment and innovation. We have already developed and brought to market climate-neutral and digital solutions to address the industry’s various challenges,” she emphasised.

However, Müller stressed the need for urgent infrastructure development, stating, “The biggest obstacle to the widespread adoption of climate-neutral drives is the necessary infrastructure – especially charging stations, grid expansion, and hydrogen refuelling stations. Berlin and Brussels need to establish an infrastructure initiative and implement it as quickly as possible.”

According to the VDA, visitor satisfaction at IAA Transportation 2024 exceeded 90% (a remarkable achievement), while 45% of attendees hailed from outside Germany. The Netherlands, China, and Sweden were the most represented nations. The event’s ability to attract decision-makers was notable, with a 30% increase in trade visitors holding leadership positions compared to 2022. Over 50% of attendees confirmed plans to invest in the next six months to 11 years.

One of the standout features of the event was the opportunity for attendees to test the latest emission-free commercial vehicles (CVs). A total of 60 vehicles were available for test drives and demand was overwhelming, with over 6,300 test drives completed – a 15% increase on previous records. These included more than 2,200 test drives on cargo bikes.

The fair attracted significant media attention, with over 1,400 journalists from 52 countries in attendance. More than half of these journalists were from abroad, once more highlighting the event’s global standing. Exhibitors held over 80 press conferences on press day, meaning journalists were running from pillar to post.

Over the next 20 pages, we will present some of the highlights of those press conferences, and we will also give an overview of some of the particularly fascinating exhibits. The companies are listed in alphabetical order.

BYD

There was a massive Chinese presence at this year’s IAA, and BYD was one of the (many) exhibitors from that country. Taking centre stage at the company’s exhibition stand was the new BYD E-VALI, a 3.5/4.25-t light commercial vehicle (LCV) designed specifically for Europe.

This pure-electric van is engineered for last-mile and parcel delivery services, combining substantial cargo capacity with innovative EV technology. With a range of 220 to 250km, depending on the variant, the BYD E-VALI offers a practical, eco-friendly solution for commercial fleets. The E-VALI also boasts a high level of driver comfort, with an ergonomically designed cabin and advanced driver assistance systems (ADAS).

Another major highlight was the European debut of the BYD EYT 2.0, an electric yard tractor designed for ports, terminals, and distribution centres. Featuring a modernised design, including a characteristic offset cab for enhanced comfort and visibility, the EYT 2.0 offers impressive performance with a gross combined weight (GCW) of up to 75 tonnes. Its 16-hour working time, supported by quick charging intervals, makes it ideal for high-demand environments. This yard tractor represents a significant step towards decarbonising industrial logistics, where eco-friendly alternatives are becoming increasingly critical.

On top of these launches, BYD also showcased its ETM6, a 7.5-t pure-electric truck designed for inner-city distribution. The ETM6 offers a range of up to 200km, making it a versatile and manoeuvrable option for zero-emission urban deliveries. With a streamlined design and an advanced driver-focused cab, the ETM6 is built on BYD’s proprietary ePlatform, ensuring energy efficiency, safety, and performance. The truck’s quick DC charging capability, reaching 100% in just one hour, adds further convenience for operators.

Lastly, BYD introduced the ETH8, a 19-t eTruck with a versatile multipurpose platform. Designed for various commercial applications, including logistics and sanitation services, the ETH8 offers a range of 250km and a spacious, ergonomic cabin. Like the ETM6, the ETH8 utilises BYD’s advanced eTruck platform, providing optimal performance, efficiency, and ease of maintenance.

DAF

DAF Trucks unveiled an impressive array of innovations designed to set new standards in efficiency, safety, and driver comfort.

The company announced the optimisation of the PACCAR MX-11 and MX-13 engines, which feature innovations like new valve timing, a dual drive coolant pump, and a two-cylinder air compressor. Additionally, DAF introduced improvements to its SR1344 rear axle, which includes a new pinion design that enhances strength and durability while supporting the highest power ratings. The trucks also feature Predictive Cruise Control and the DAF Digital Vision System, providing significant gains in fuel efficiency and reducing CO2 emissions.

The introduction of PACCAR Connect, a 10-year fleet management platform, allows for real-time monitoring of vehicle and driver performance, enabling over-the-air updates and seamless integration with existing logistics systems. This feature improves overall fleet efficiency and reduces operational costs.

DAF continues to focus on safety, with all New Generation trucks featuring a comprehensive suite of (DAS) These include the Advanced Emergency Braking System, Lane Departure Warning, and Speed Limit Recognition, ensuring the highest levels of safety on the road. DAF also introduced the Drowsiness Detection system, which monitors the driver’s alertness to enhance road safety further.

Driver comfort has been prioritised with updates to the driveline, resulting in reduced noise levels and a smoother driving experience. The new shifting strategy for the transmission also contributes to better driveability, ensuring a comfortable ride for long-haul drivers. Connected Truck Navigation, integrated through PACCAR Connect, allows for direct route planning, improving convenience and reducing driver stress.

DAF showcased its full range of EVs, including the XB, XD, and XF models, which cater to city, regional, and long-haul transport. These electric trucks feature modular battery packs offering ranges of up to 500km. The use of Lithium Ferro Phosphate (LFP) batteries ensures superior thermal stability, long life, and safety, positioning DAF as a leader in the shift towards zero-emission transport.

With first-class charging stations and energy storage solutions from PACCAR Power Solutions, DAF provides a complete service package to support customers in transitioning to electric fleets. DAF also presented future technologies like the PACCAR MX Hydrogen Engine and the e-Axle, showcasing their ongoing commitment to sustainability and innovation.

DAF’s president, Harald Seidel, highlighted the company’s dedication to driving progress: “The best trucks on the market have become even better. Our innovations in efficiency, safety, and driver comfort – alongside our battery-electric vehicles – demonstrate that DAF is ready for the future.”

DAIMLER TRUCK

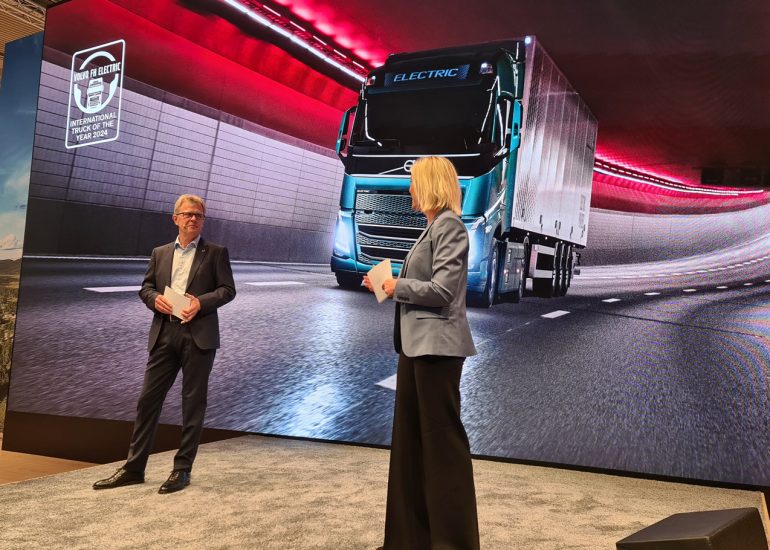

The star of the show on the Daimler Truck stand was the new Mercedes-Benz eActros 600, an all-electric heavy-duty truck which was named the 2025 International Truck of the Year during the exhibition.

With an impressive battery capacity exceeding 600kWh and a specially developed, highly efficient electric drive axle, the eActros 600 can travel up to 500km on a single charge. What’s more, this range was recently tested under real-world conditions, with the truck carrying a 40-tonne load.

Over the course of a seven-week European tour, two near-production prototypes of the eActros 600 travelled more than 15,000km across 22 countries, demonstrating its remarkable efficiency and performance. Powered entirely by public charging stations, the trucks achieved an average consumption of 103kWh/100km (the equivalent of 10 litres of diesel), a milestone in energy efficiency for heavy vehicles. The eActros 600 was able to recuperate 25% of its energy, further extending its range.

This rigorous testing proved that the eActros 600 could cover daily distances of over 1,000km when incorporating intermediate charging during mandatory driver breaks. This efficiency makes it not only an environmentally friendly solution but also a commercially viable alternative to diesel-powered trucks for fleet operators.

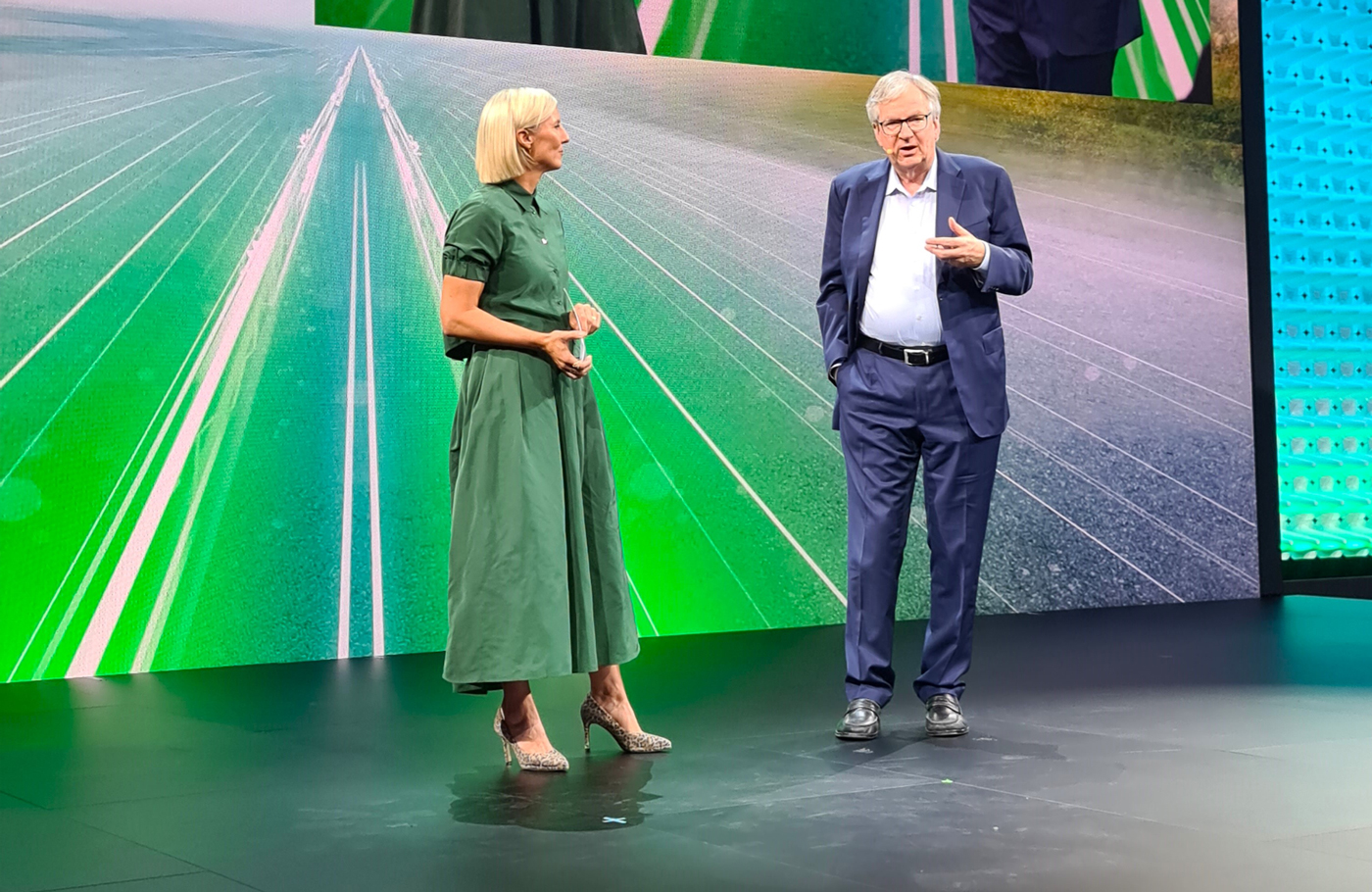

During the company’s press event, Martin Daum, outgoing CEO of Daimler Truck, emphasised that while the company has delivered on its promise of producing efficient, zero-emission vehicles, the lack of adequate infrastructure remains a significant hurdle. “We are supplying battery-electric series vehicles in the quantities that our customers demand,” Daum said, “but the charging infrastructure must now follow.”

The need for comprehensive charging networks was echoed by Karin Rådström, who has succeeded Daum as CEO in October 2024. She highlighted the eActros 600 as a robust alternative to diesel trucks, pointing out that its profitability for operators hinges on the availability of public charging stations. “Politicians, the energy sector, and industry must work together to advance the expansion of the public charging infrastructure,” she urged.

To support this transition, Daimler Truck introduced the TruckCharge brand, designed to streamline the e-mobility experience for customers. This service offers complete solutions for electrified depots, including Fleetboard Charge Management, which provides real-time insights into fleet charging activities, and a cashless charging card for on-the-road charging. With these tools, Daimler Truck aims to make e-mobility both accessible and profitable for businesses.

Daimler Truck’s eActros 600 was also put to the test during the company’s “Media Night”, when the truck embarked on a night-time trip to Berlin and back (it collected yummy doughnuts for the journalists to munch on the following day). However, the trip also had a more serious aim. “We want to demonstrate the truck’s suitability for everyday use while sending a powerful message to policymakers in both Berlin and Brussels: Daimler is ready with emission-free trucks, but the infrastructure must catch up,” said Rådström.

While battery-electric trucks like the eActros 600 are perfect for many applications, Daimler Truck is also investing heavily in hydrogen-powered vehicles, which are particularly suited for demanding, long-distance transport. The Mercedes-Benz GenH2 Truck, powered by a hydrogen fuel cell, was another star of this year’s IAA. This vehicle demonstrated its capabilities last year during the #HydrogenRecordRun, covering 1,047km across Germany on a single tank of liquid hydrogen.

The GenH2 Truck has now reached a stage of development where it is undergoing customer trials with companies such as Amazon and Air Products. These tests will provide invaluable feedback on how hydrogen-powered trucks perform in real-world logistics operations and will inform Daimler’s strategy for bringing these vehicles to market.

In addition to the company’s focus on decarbonisation, Daimler Truck is looking towards the next technological revolution: the software-defined vehicle. This concept, which Daimler Truck plans to roll out over the next decade, promises to transform trucks into highly intelligent machines that can process and analyse massive amounts of data in real time.

Andreas Gorbach, Daimler Truck’s chief technology officer, explained that the future of the truck lies in its ability to adapt and improve continuously. “The future of the truck is emission-free and based on software,” he stated. Daimler is working closely with the Volvo Group to develop a standardised platform for software-defined CVs. These trucks will be able to process topographical data, traffic conditions, and even electricity prices to optimise routes and reduce costs.

Software-defined vehicles could revolutionise the industry by offering advanced safety features, such as Active Brake Assist 6 and Connected Traffic Warnings, which would allow trucks to communicate hazards with other vehicles. In the long run, these trucks may even handle administrative tasks, such as automating freight documentation or reserving parking spaces and charging stations.

Daimler Truck’s presence at the IAA was not limited to long-distance transport. The company also showcased a variety of other vehicles designed to meet the diverse needs of the commercial sector. The FUSO Next Generation eCanter, presented in various configurations, is a fully electric light truck that has already proven its versatility in urban environments. With more than 100 variants, it covers 85% of conventional vehicle applications, making it an ideal choice for eco-friendly transport.

The Mercedes-Benz Actros L, a conventionally powered truck with improved aerodynamics, also made its debut at IAA. Featuring futuristic design elements and fuel-saving technology, it continues to set the standard for heavy-duty trucks.

On the public transport front, Daimler Buses unveiled the eCitaro K, a battery-electric city bus with a shorter wheelbase for improved manoeuvrability. With the capacity to transport up to 84 passengers and a range of more than 300km, the eCitaro K is perfectly suited for urban public transport.

FORD TRUCKS

At the IAA, Ford Trucks showcased an impressive lineup of next-generation products and innovations. One of the standout exhibits was the new F-LINE series, which drew significant attention for its modern design and exceptional versatility. Available in three segments – road, construction, and tractor – the F-LINE series was designed to provide maximum efficiency and uptime. Equipped with connected vehicle technology and advanced safety features, the series caters to a wide range of commercial needs, offering superior performance in demanding conditions.

Another key attraction was the acclaimed F-MAX, which has already gained global recognition for its spacious cabin, high-performance engine, and state-of-the-art technological features. At IAA 2024, Ford Trucks displayed not only the standard F-MAX but also a limited edition F-MAX Select and a customised version that featured exclusive interior and exterior details. These additions enhanced the driving experience by offering even more comfort, safety, and visual appeal, reinforcing Ford Trucks’ focus on driver satisfaction. The F-MAX also featured a mirror camera system.

Ford Trucks also emphasised its broader vision for the future of transportation under its “Generation F” initiative, which focuses on zero-emission, connected, and autonomous technologies. A major part of this vision includes the development of 100% electric trucks, which are being designed and tested entirely by Ford Trucks engineers, and are expected to hit the roads by 2025.

IVECO

Iveco exhibited a comprehensive line-up of trucks powered by a variety of energy sources, from hydrogen and bio-methane to electricity and natural gas.

One of the highlights of the Iveco stand was the global premiere of two new battery-electric vehicles (BEVs). The first, the S-eWay Rigid, a heavy-duty electric truck designed entirely by Iveco (including the software) offers a driving range of up to 400km and rapid charging capabilities that provide an additional 200km of range in under 45 minutes. Equipped with an FPT Industrial electric axle and a battery capacity of up to 490kWh, it complements the existing articulated version of the S-eWay series.

Also making its world debut was the eMoovy, a light electric chassis cab aimed at urban applications such as door-to-door deliveries. Manufactured by Hyundai and customised for the European market by Iveco, the eMoovy represents the ongoing partnership between the Iveco Group and Hyundai Motor Company. This compact electric vehicle, with a range of up to 320km, boasts the fastest charging time in its segment, offering an additional 100km of range in just 10 minutes. Designed for the 2.5 to 3.5-tonne category, the eMoovy delivers zero-emission performance while offering car-like comfort in its cabin.

In addition to these premieres, Iveco also displayed innovative alternative fuel technologies. Visitors could view a prototype of the S-Way truck, featuring an XCURSOR 13-litre hydrogen internal combustion engine, and a hybrid heavy-duty truck concept equipped with an electric axle and a CURSOR 9-litre H2 engine.

FPT Industrial further expanded on its vision with a dedicated exhibit space at the IAA. Here, interactive displays showcased the XCURSOR 13, a versatile multi-fuel engine designed to operate on diesel, natural gas, and hydrogen, providing flexibility for various energy infrastructures. The CURSOR 9 H2 engine, another key feature of the stand, demonstrated Iveco’s commitment to zero CO2 emissions in heavy-duty transport. The brand also introduced the N67 Hythane prototype, which runs on a blend of hydrogen and methane, underlining Iveco’s pursuit of innovative fuel solutions. In addition, FPT Industrial highlighted its latest electrified axles for light, medium, and heavy applications, as well as battery systems for lighter commercial vehicles.

Speaking at the event, Olof Persson, CEO of Iveco Group, emphasised the significance of the fair: “IAA Transportation is an important event for the global transport industry and an ideal forum for us to introduce our innovative line-ups of vehicles, engines, and services.”

Persson also reiterated the brand’s long-standing leadership in alternative fuel technologies, noting that Iveco has been a pioneer in the field for over 25 years. He stressed that Iveco is fully equipped to cater to any direction the industry takes, with solutions spanning natural gas, hydrogen combustion engines, BEVs, and hydrogen fuel cell propulsion systems.

MAN TRUCK & BUS

Under the banner “Simplifying Business”, MAN showcased a diversified range of trucks powered by electric, hydrogen, and state-of-the-art diesel engines.

One of the standout moments from MAN’s exhibit was the world premiere of the MAN eTGL, a 12-tonne battery-electric truck designed specifically for light distribution transport. With a range of up to 235km, a payload capacity of up to 6,600kg, and the ability to recharge in just 30 minutes, the eTGL is set to make a significant impact on urban logistics. This new electric truck is ideal for tasks such as food distribution, retail deliveries, and catering services, particularly in city environments where noise and emissions restrictions are increasingly stringent. The eTGL expands MAN’s already robust electric truck portfolio, offering operators a versatile, zero-emission option for urban and suburban routes.

MAN’s electric truck range was further bolstered by the eTGS and eTGX, the heavier siblings of the eTGL. These trucks offer flexible configurations, with three, four, five, or six modular batteries that can be positioned variably to suit different transport needs. The range of these trucks is impressive, but the star of the show was the eTGX 6×2 chassis, featuring a seventh high-voltage battery. With a usable capacity of 560kWh, this configuration allows the truck to achieve a range of approximately 650km on a single charge, making it ideal for long-distance haulage. The additional battery power also supports auxiliary units, demonstrating MAN’s commitment to meeting the needs of various industries.

Customer interest in MAN’s electric trucks has been significant, with over 2,300 orders and inquiries already received for the eTGS and eTGX models. One of the most notable deals was a major order from France for 100 electric trucks, underscoring the growing demand for zero-emission CVs across Europe.

While MAN’s electric trucks attracted much attention, the company was another to emphasise the importance of expanding charging infrastructure to support the growing number of EVs on the road. Alongside Daimler Truck and Volvo Trucks, MAN is a partner in the Milence joint venture, which aims to build 1,700 charging points in the coming years. This initiative is crucial as the industry moves towards the ambitious goal of establishing 50,000 charging points by 2030. Furthermore, MAN’s partnership with E.ON is set to create 170 charging locations across Europe, with 400 charging points to be installed along major transport routes. This collaboration aims to ensure that electric trucks have access to reliable and efficient charging infrastructure, helping to accelerate the transition to zero-emission freight transport.

In addition to its electric trucks, MAN introduced a prototype of the hTGX, a hydrogen combustion engine truck that garnered significant attention at IAA. Equipped with a 16.8-litre engine capable of producing 520hp and 2,500Nm of torque, this truck is designed for heavy-duty applications that require a robust and reliable powertrain. The hydrogen tanks, which operate at 700-bar high pressure and can store 56kg of hydrogen, allow the hTGX to travel up to 600km on a single tank.

MAN sees hydrogen as a complementary solution to battery-electric trucks, particularly for specialised applications like heavy transport and areas where it is challenging to establish charging infrastructure. The hTGX is expected to launch in a small series of 200 vehicles by 2025, with deliveries planned for Germany, the Netherlands, Norway, Iceland, and select non-European markets.

While MAN is pushing hard towards zero-emission solutions, it recognises that diesel technology will remain vital during the transition. To that end, MAN introduced its new PowerLion drivetrain, which is set to power the TGS and TGX series from 2025 onwards. The drivetrain includes the D30 six-cylinder engine and the MAN TipMatic 14 gearbox, which together promise to reduce fuel consumption and CO2 emissions by up to 4%. This improvement translates into cost savings of over €20,000 over the vehicle’s lifecycle, as well as a 35-tonne reduction in CO2 emissions.

The engine’s efficiency, combined with enhanced aerodynamics and a new braking system, allows MAN to offer a more sustainable diesel-powered option that meets the demands of operators who are not yet ready to transition to fully electric or hydrogen-powered trucks.

Safety was another key theme at MAN’s stand, with the company unveiling new safety and assistance systems designed to protect vulnerable road users like pedestrians and cyclists. These systems are already integrated into MAN’s TGE vans, which feature cutting-edge technologies like the Cruise Assist Plus system with Emergency Assist. The emergency assistant continuously monitors the driver’s activity, and if the driver becomes unresponsive, the system can safely bring the vehicle to a halt, activate the hazard lights, and even unlock the doors for emergency services.

In line with MAN’s focus on sustainability, the company’s stand at IAA was constructed using reusable materials, with a strong emphasis on reducing waste and extending the lifecycle of products. Aluminium, wood, glass, and carpet tiles replaced traditional laminate and plastic, while printed materials were minimised. Even the food served at the stand was carefully managed, with any leftovers being donated to local food banks, further highlighting MAN’s commitment to reducing its environmental impact.

MICHELIN

Michelin introduced two new products: the Michelin X Line Energy 3 and the Michelin X Multi Energy 2, both of which are positioned to set new benchmarks in the industry for fuel savings and lateral grip, without compromising on durability, mileage, or retreadability.

The Michelin X Line Energy 3 is designed for long-distance journeys and sets a new standard for fuel efficiency. It offers significant fuel savings, beating the premium brand average by 0.62L/100km, which translates to annual cost savings of between €700 and €2,200 per truck. Additionally, lateral grip performance has been improved by 4.42% for new tyres and 2.02% for two-thirds worn tyres, ensuring enhanced safety on the road. These innovations position the X Line Energy 3 as a top contender for long-haul fleet operators focused on both efficiency and performance.

For regional and highway transport, Michelin presented the Michelin X Multi Energy 2, which outperforms competitors with fuel savings of 0.16L/100km, delivering cost savings of between €100 and €380 per truck annually. In terms of lateral grip, the tyres offer a 5.06% improvement when new and a 5.67% improvement when partially worn, making them a durable and reliable option for shorter distance hauls.

The company’s innovative tyre technologies are further enhanced by Michelin Connected Mobility, a suite of connected services designed to optimise fleet management. By integrating data analysis of vehicle and driver performance, Michelin helps fleet managers reduce maintenance times, avoid unnecessary tyre changes, and minimise vehicle downtime. This leads to fuel savings of up to 12%, significantly improving operational efficiency.

Michelin’s vision of providing long-lasting, high-performance tyres remains a core focus as the company looks to renew over 80% of its truck tyre ranges in the next five years.

PROMETEON

The Prometeon Tyre Group unveiled two world premieres: the Prometeon C02 Coach and SuperFleet.

The Prometeon C02 Coach, a new addition to the company’s bus tyre range, is designed to meet the growing demand for environmentally friendly solutions. The C02 Coach is the first Prometeon tyre to achieve an A-rating for rolling resistance, a milestone that underscores the company’s commitment to reducing CO2emissions and operational costs for fleets.

What sets this tyre apart is its sustainable construction, with 80% of its materials being either certified recycled or sourced from renewable resources. The tyre’s low rolling resistance, measured at below 4N/kg, enables a reduction in fuel consumption by 0.9L/100km. For a fleet of 50 vehicles driving 130,000km per year, this translates into savings of approximately €102,000 annually, alongside a 157-tonne reduction in CO2 emissions.

The Prometeon C02 Coach is available in multi-axle and drive versions, both featuring a load index increased to meet the demands of hybrid and full EVs. The tyres also come equipped with RFID technology, enabling advanced tracking and management throughout their lifecycle. The C02 Coach is expected to hit the market in the second half of 2025, making it a key player in the future of sustainable transport.

Prometeon also launched SuperFleet, a comprehensive fleet management solution tailored to the diverse needs of modern fleets. Built on the foundation of the SuperTruck network, which now boasts 400 dealers across Europe, SuperFleet offers a range of services that aim to improve operational efficiency and sustainability for fleet operators.

The SuperFleet solution is customisable, catering to fleets of different sizes, types, and geographical locations. It provides fleet managers with tools to optimise tyre performance, reduce costs, and increase overall fleet efficiency. By integrating cutting-edge technology and professional support, SuperFleet enhances fleet management at every stage, from tyre selection to end-of-life recycling.

RENAULT

Renault showed one of the quirkiest and coolest vehicles at the fair, namely the futuristic Estafette Concept, an all-electric van designed to meet the growing demands of urban logistics and professional users. This innovative van, which draws inspiration from Renault’s iconic 1959 Estafette, is set to revolutionise the utility vehicle landscape with its cutting-edge features and practical design.

The Renault Estafette Concept embodies a perfect blend of retro charm and modern technology. While its design pays homage to the original Estafette via its rounded headlamps and compact build, the new model is packed with advanced technology aimed at making life easier for delivery drivers, tradespeople, and retailers. Built on Renault’s FlexEVan platform, the Estafette Concept is an all-electric van poised to address the challenges faced by professionals in the age of e-commerce, urban traffic restrictions, and the growing need for zero-emission vehicles.

Just like its predecessor, the Estafette Concept was designed with practicality in mind. The original 1959 Estafette was the first Renault vehicle to feature a front-mounted powertrain, maximising the space for loading. The new Estafette 4.0 continues this tradition of innovation, with a focus on keeping drivers and goods safe while ensuring swift loading and unloading. The van’s compact size makes it ideal for navigating tight urban spaces, while its spacious interior provides ample room for cargo. The Estafette Concept is also highly functional. Measuring 4.87m in length and 1.92m in width, it fits comfortably in standard parking spots, making it an agile option for urban use. Despite its modest footprint, the van stands tall at 2.59m, providing a surprisingly spacious interior that allows the driver to easily move between the cockpit and cargo area.

Renault has equipped the van with a series of features designed to streamline the loading and unloading process. The pocket sliding side doors open with a simple motion, saving time and reducing strain on the driver’s wrist, especially during multiple stops. At the rear, a shutter door rolls up neatly, allowing for full-height access to the cargo area, which boasts a capacity similar to the Renault Trafic L1H2 at close to 7.1m3. This design eliminates the need for clearance space behind the van, allowing it to back up directly to a loading dock for efficient loading.

One of the most striking design elements is the triptych-shaped windscreen, which wraps around the front and side of the van, giving the driver a panoramic view of their surroundings. The sleek, high-tech look of the windscreen, which resembles a helmet visor, hints at the vehicle’s advanced safety features and offers both style and practicality.

Inside the Estafette Concept, Renault has designed a cockpit tailored for efficiency and comfort. The vibrant yellow interior is energising, and the single driver’s seat sits on a platform that allows for easy manoeuvrability. The driver can effortlessly swivel the seat to access the cargo area, providing a seamless transition between driving and unloading. The van’s dashboard is equally impressive, packed with technology to support the needs of modern professionals. It features a seven-inch screen for essential driving information and a larger 12-inch display for multimedia and navigation. The dashboard has no visor in the steering wheel area, giving the driver an unobstructed view, while customisable widgets provide quick access to frequently used functions.

Built incorporating feedback from professionals and with the goal of improving efficiency and safety, the Estafette Concept is set to enter production in two years’ time. We can’t wait!

TESLA

Tesla had a surprisingly small stand, displaying a 6×4, while another 6×4 was available for test drives. Alas, journalists were not actually allowed to drive the vehicle (they could go along as a passenger). Plus, the “test drive” programme was cut short “because the driver had to return to the US”. Tesla staff members revealed the weight of the Semi during the show. The “standard range” version (500km range) weighs a maximum of 9,000kg and the “long range” (800km range) a maximum of 10,500kg. While these figures apply to the US version of the Semi, they will probably be the same for the European version. Tesla claims that the trucks consume around 100kWh/100km.

Currently, Tesla claims to operate a fleet of around 100 trucks on US roads, with the majority being used by PepsiCo. Collectively, these trucks have logged 7.5 million kilometres. One vehicle, in particular, has travelled over 400,000km in just 18 months of operational use under maximum load.

THERMO KING

With a clear focus on electrifying the cold chain industry, Thermo King introduced a range of solutions aimed at advancing sustainability, operational efficiency, and environmental responsibility.

Thermo King’s stand featured the company’s expanded E-Series electric transport refrigeration unit portfolio, catering to both small and large trucks. This portfolio included high-performance electric units like the Advancer-e Spectrum multi-temperature trailer refrigeration unit, alongside cutting-edge digital and power management solutions. Key among these was the AxlePower energy recovery and management system, as well as Energ-e and E-Coolpac battery solutions.

Speaking at the event, Claudio Zanframundo, president of Thermo King EMEA Truck, Trailer, Bus and Global Marine, Rail, Air, emphasised the company’s commitment to electrification. “Our fully electric and hybrid product lineup at the IAA marks another pivotal moment following our commitment to deliver electric products in every segment of the cold chain by 2023,” he stated. Zanframundo highlighted Thermo King’s goal of setting new benchmarks for efficiency and sustainability, benefiting both customers and the planet.

One of the most significant launches was the Advancer-e Spectrum. This all-electric, multi-temperature trailer refrigeration unit was designed to provide precise temperature control across various cargo types. The A-500e Spectrum model offers flexibility for complex delivery routes and is engineered to operate without emissions, making it ideal for urban and late-night deliveries. Its advanced design allows compatibility with multiple power sources, including the AxlePower self-charging energy recovery system and the E-Coolpac battery pack, making it adaptable for future demands.

Thermo King revealed its Large Truck E-Series units, which cater to trucks between 7.5 to 26 tonnes. These units, available in both single- and multi-temperature configurations, feature advanced technology for optimal performance, including HVDC connections and variable speed control. The units are designed to operate efficiently on both BEVs and internal combustion engine (ICE) vehicles, reducing fuel consumption and emissions. Real-time connectivity allows fleet managers to monitor efficiency through telematics, while the units’ robust design ensures low maintenance and maximum uptime.

Thermo King also focused on the last-mile delivery market with its E-100e and E-200e refrigeration units, designed for vans and light commercial vehicles up to 12m³. These units boast compact, lightweight designs and feature reverse cycle heat pump technology, which enhances cooling performance. Their smart controls further optimise compressor speed based on ambient conditions, improving energy efficiency and ensuring reliable operation in diverse conditions.

VOLKSWAGEN

Volkswagen Commercial Vehicles made headlines with the world premiere of the highly anticipated seventh-generation Transporter. This new iteration of the iconic van was unveiled in multiple configurations, including panel van, Kombi, double cab with a platform body, and the Caravelle version. Set to be launched in South Africa in the second half of 2025, the new Transporter is poised to revolutionise the commercial vehicle market with its blend of innovation, space, and performance.

One of the standout features of the new Transporter is its collaboration with Ford, leading to a completely redeveloped design. The van will feature a digital cockpit with a 12-inch display and a 13-inch touchscreen infotainment system, offering a modern and intuitive user experience. Cargo space has been significantly increased, with the standard version providing 5.78m3 and the extended version up to 9m3. With a payload capacity of 1.33 tonnes and the ability to tow up to 2.8 tonnes, the new Transporter is designed to handle a wide range of commercial needs.

In terms of power, the Transporter will come equipped with a 110-hp turbo diesel engine. For the first time in the model’s history, Volkswagen will also offer plug-in hybrid and all-electric versions, reflecting the brand’s commitment to sustainability and adapting to the changing needs of modern logistics and transport.

Accompanying the launch of the Transporter is a new advertising campaign starring Jason Statham, the action star best known for his role in “The Transporter” film series. Statham’s involvement adds a cinematic touch to the campaign, embodying the toughness and versatility of the vehicle.

The IAA marked the start of pre-orders for the new Transporter, with sales expected to pick up rapidly as the vehicle hits global markets.

WINDROSE

Windrose presented its 6×4 and 4×2 EVs. The two long-haul trucks – with a range of 670km, a peak power of over 1,000kW, and a 729kWh battery – already in use by customers in China. Founded by Wen Han, a 35-year-old entrepreneur, Windrose has quickly gained traction as a significant player in the EV market. Han’s approach has been to keep the company lean and agile, focusing on efficiency in both production and design. We are told that the trucks are built in Belgium, but all parts are sourced from China, a decision that has enabled Windrose to keep costs competitive while ensuring a reliable supply chain.

The 2026 IAA Transportation will take place in Hanover from 15 to 20 September. See you there!

Published by

Charleen Clarke

focusmagsa