Blossoming in the dark

Blossoming in the dark

While the Covid pandemic forced many organisations to cancel trade fairs and congresses in the past two years, the Test Camp Intralogistics* has developed almost unnoticed. We talk to Anita Würmser, Test Camp Intralogistics MD and juror for both the International Intralogistics and Forklift Truck of the Year (IFOY) Awards and the Logistics Hall of Fame, about this state-of-the-art intralogistics event.

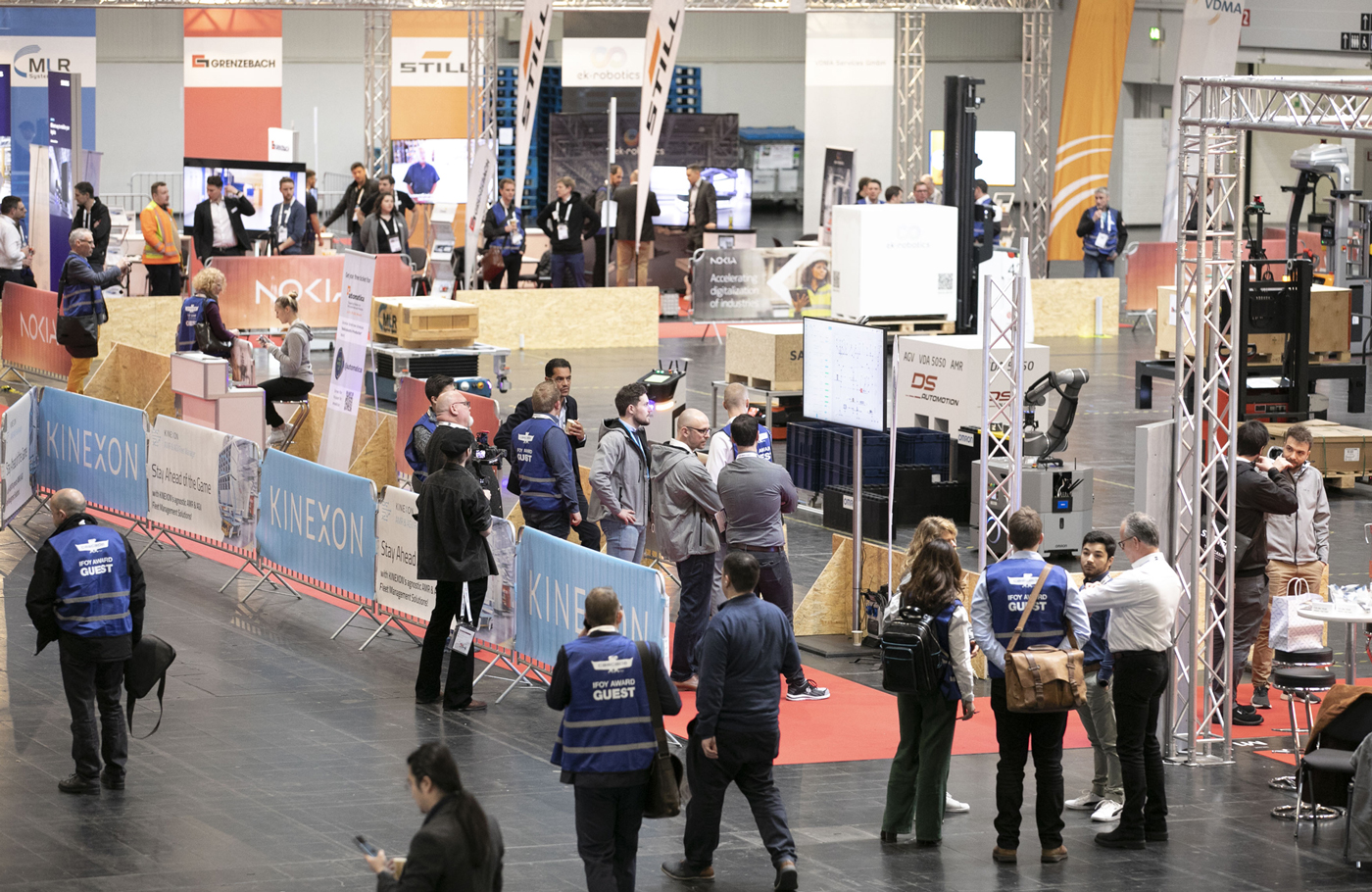

The Test Camp Intralogistics and IFOY Test Days have grown significantly compared to last year. More than 1 200 participants, up from last year’s 950, travelled to Messe Dortmund in the west of Germany to test equipment and solutions, including numerous world firsts. The finalists for the IFOY Awards – considered the Oscars of supply chain management – were joined by more than 100 innovations, which were available for business-to-business (B2B) visitors to try out first-hand in 10 000 m2 of exhibition and test area.

“Cancelled” was the word of 2020 and 2021, continuing in the beginning of 2022. Test Camp Intralogistics has taken place three times; how do you establish an attendance fair with almost 1 000 participants in the middle of a lockdown?

I have been asked that countless times. We just did it. In a nutshell, it was 200% work, 100% courage, 0% planning security. The authorities were tough but helpful, while the regulatory requirements were gigantic, not to mention the risk. In the end, momentum was gained from the courage of everyone involved.

Guests, exhibitors, testers, team, judges – they all came to test innovations and keep the business going, and everyone followed the rules conscientiously. It was a bit scary, though, when we were in the middle of the lockdown in 2021 with 650 people all alone in the hotel and on the exhibition grounds.

What response did your trade show receive?

The response was surprisingly positive. I expected a [debacle], but quite the opposite occurred. In some cases, we were even cheered on and media coverage exploded – 960 media outlets in 79 countries reported on us. Only one private person wanted to have Test Camp banned, but that actually helped us.

Can you explain that a bit more?

As a result of the complaint, our Covid protocols and security concept were examined particularly closely; ultimately, they were rated as exemplary. We also benefited from the fact that exhibitor and visitor access to our event is limited anyway. After all, Test Camp is a restricted test event for the industry, so don’t call it a trade fair!

Booths, exhibitors, visitors… Why put so much emphasis on it not being a trade fair?

This is a new event format: an interactive event for selected innovations for decision-makers. A trade fair is designed for mass exposure. This is by no means something negative; the goal is full halls and aisles and the widest possible range of exhibitors. In contrast, however, we get nervous when the hallways and booths are full, because queues form at the test stations and boxes, and the testing no longer works. At a trade show, anyone can exhibit; with us it’s preselected. At a trade show you have to find your own way around, while at Test Camp we guide visitors through the hall on highlight tours.

Not everyone can exhibit, and not everyone gets in, so how do you make the selection?

Besides a limited ticket contingent, along with our exhibitors we invite top-level B2B guests with a concrete innovation and investment interest for hands-on testing. The target group comprises decision-makers who not only want to look at the best innovations, but experience them live. They want to test, drive, and try out these products themselves. These are the people who want to know what’s coming next.

We pay particular attention to presenting an interesting mix and match. The IFOY Awards finalists already represent the year’s leading innovations. In addition, only new and innovative products are shown and we carefully research and approach companies worldwide that have innovations and new products to offer.

Is it true that the Test Camp was born out of the IFOY Awards?

Correct, but the Test Camp is now an independent event. The IFOY audit of the finalists, the so-called IFOY Test Days, still takes place as part of the Test Camp. For a long time, only finalists, jurors, testers, and IFOY partners had access to the IFOY Test Days – all in all, no more than 150 people.

During IFOY Test Days 2017/18, some jurors invited contacts from their readership (the IFOY jury consists of editors-in-chief from leading logistics magazines worldwide). A few logistics service providers were there, an automotive supplier and manufacturer, a DIY store manager, and a furniture retailer from the region; all were excited about the opportunity to test the IFOY finalists themselves.

So, we thought, why not allow a limited number of B2B guests? In early 2020, we invited 50 guests as a test run. By 2022 there were almost 1 000 participants, which rose to more than 1 200 this year.

Some might say that around 1 200 participants don’t sound like a lot?

I actually think around 1 200 people over two days is the optimum size. Exhibitors couldn’t manage much more and it really depends more on who is there. Our visitors make decisions worth up to hundreds of millions of euros; they want to see innovations in concentrated form, and get an effective and efficient overview of the state of the technologies. They spend a correspondingly long and intensive time looking at the exhibits. Some even throw themselves under the equipment so that no detail remains undiscovered. If all you want to do as an exhibitor is collect lots of leads, then Test Camp is definitely the wrong place to be.

Which industries do visitors come from?

The strongest group comprises logistics service providers, especially contract logisticians. The automotive original equipment manufacturers are also almost fully represented. E-commerce and stationary retail are well represented, as well as the consumer goods and beverage industry, mechanical engineering, chemicals, and pharmaceuticals.

The Test Camp positions itself as a sustainable event. Everybody is nailing these colours to their masts now, so how is Test Camp different?

Of course, wherever waste, transport, energy, or resources can be saved, we do so, but that’s not the crucial point. Sustainability is so easy to say, but it’s another story doing something truly sustainable without certificate trading or pseudo-green marketing. That’s a fundamental decision and it just changes everything. Brands are getting a completely different face and a different business model is emerging. We had the advantage of the green field and wanted to do something meaningful – an event that fits the times and inspires customers and exhibitors alike. For us, sustainability was therefore less a question of “if” and more a question of “how”.

Can you give us an example?

We didn’t want to claim sustainability as our motto and at the same time leave behind gigantic mountains of garbage after the event. That’s why, for example, the question arose about how much stand construction to do, and whether it was necessary at all.

We could have created a test fair with individual stand construction and show elements. That would certainly have been more lucrative, but not sustainable. The hall and test areas don’t have to sparkle, they have to be functional. All stands are therefore centrally planned, set up, and dismantled. Branding is simple and standardised; custom booth construction is not permitted, nor are shows or superfluous decorations that are not necessary for the functionality of the exhibit.

Almost all materials are reusable: we use aluminium trusses, Mannesmann fencing, and rental furniture from nearby service providers. Carpet is shredded after the camp and reprocessed into new carpets, while central catering saves water and resources. The hotel is 100 m from the hall, and we use green electricity. It boils down to minimalism – true innovation doesn’t need decoration.

Will exhibitors and visitors settle for less?

What is the most important and, at the same time, the most difficult factor for success in logistics? It’s technology. If you rely on the wrong software and hardware, or if you miss the crucial innovation, you’re out.

That’s why many companies are open to new ways of doing things. Our focus on innovation and new products, along with the all-inclusive approach, offers many advantages. It also makes a difference whether you work with a humanoid robot, operate a horizontal order picker, try out an exoskeleton, drive a forklift, or just look at it all.

How does the “self-testing” work?

We take visitors on highlight tours of all the exhibitors to give them an overview of the innovations. Each exhibitor presents its innovations in two or three minutes, then visitors can test drive or test individually. Test areas are cordoned off, and we hand out high-visibility vests. Safety shoes are also mandatory in the test areas.

What innovations were on the agenda at this year’s Test Camp Intralogistics?

A wide range of innovations was available in the test arena: from forklifts and automated warehouse equipment to Automated Guided Vehicles (AGVs) and state-of-the-art software, specials, and robotics solutions.

Expert discussions revolved around topics such as digitalisation, process cost reduction, artificial intelligence, and sustainability. Visitors got food for thought in nine thematic highlight tours and six panel discussions featuring top-class experts from Europe, the US, and China. The sessions focused on automation, warehouse trucks, exoskeletons, and technology trends. Suppliers of intralogistics solutions, their users, and renowned scientists engaged in heated discussions.

Visitors also engaged in exchanges with the scientists, testers, and judges involved in the IFOY Test Days from 27 to 29 March. After going through the IFOY audit, representatives of 21 manufacturers accepted “Best in Intralogistics” certificates on behalf of their nominees.

So what’s next? What are the plans for the future?

We will emphasise the self-testing character even more and expand the talk panels. We also want to show more visions of the future alongside the new developments already available on the market.

* Test Camp Intralogistics, which took place on 29 and 30 March in Messe Dortmund, is a hands-on testing event for innovations and new developments. Decision-makers from industry, trade, and the service sector can extensively self-test selected innovations in the Test Camp’s expansive hall space.

Published by

Focus on Transport

focusmagsa