Bye bye, diesel

Bye bye, diesel

More and more companies are shunning diesel. Porsche is one such firm. Together with its logistics partners, the sports car manufacturer is using six new electric heavy-duty trucks at its Zuffenhausen, Weissach, and Leipzig sites.

Porsche is, of course, no stranger to e-mobility. The Taycan has been massively successful, sometimes even outselling the iconic 911, and many more electric cars are to come. But the company isn’t just turning its back on petrol and diesel when it comes to the cars it sells; it is also increasingly running commercial vehicles that aren’t powered by conventional fuels.

The six new electric trucks Porsche is running at the three German sites are an excellent example. These vehicles transport production materials around the plants, working alongside an existing fleet of 22 biogas-fuelled trucks. Another electric truck delivers new vehicles to Switzerland from the Zuffenhausen plant. In addition, the company is testing the use of synthetic fuels (HVO100) in a multi-year trial under the scientific supervision of the Karlsruhe Institute of Technology (KIT). For this purpose, 12 trucks from the existing fleet will be used around the Zuffenhausen plant – except that they will now be powered by re-fuels.

“Decarbonisation is an integral part of our sustainability strategy. The use of trucks with alternative drives and fuels is an important step toward achieving our ambitious goals. In doing so, we are consciously opting to use a mix of drive types that are appropriate to how the vehicles are deployed,” says Albrecht Reimold, member of the executive board for production and logistics at Porsche AG.

In the course of the decarbonisation of the company’s transport logistics, trucks powered by biogas (CNG and LNG) have been used at Porsche (as well as by others) for a long time. These will now be supplemented by the new electric trucks in standard processes. Logistics partners Keller Group, Müller – Die lila Logistik, and Elflein have also committed to operating the electric trucks using green electricity. This applies equally to the new electric truck used by the logistics company Galliker to deliver new vehicles to the Swiss market from the Porsche factory in Zuffenhausen.

In addition to the expansion of the electric truck fleet, Porsche has also been trialling the use of synthetic diesel fuels (HVO100) in its existing truck fleet since 2020. The four-year pilot scheme is being conducted in cooperation with KIT and Müller – Die lila Logistik. The logistics company is utilising 12 trucks as part of the project.

Neste’s HVO100 fuel consists of residual and waste materials and the fuel has so far been very impressive during practical use. No disadvantages have been identified compared to conventional diesel fuel – neither in terms of fuel consumption nor regarding engine reliability. The trucks, which operate a shuttle service in the greater Stuttgart area, have to date driven more than one million kilometres as part of the project; according to certified measurements by KIT, this has saved more than 800 tonnes of CO2. To ensure that meaningful data comparisons could be recorded, the test trucks – which are series-production vehicles without any modifications – have been used in parallel with diesel-powered trucks on identical routes.

Examples including the use of biogas and electric trucks, as well as the re-fuel pilot scheme, demonstrate the dedication with which Porsche is managing its transport logistics to achieve its set decarbonisation goals. This initiative also includes rail transport, which is used in particular for supplying parts and components to plants or for transporting new vehicles to the seaports, where the vehicles are then prepared for export to destinations outside Europe. Vehicle production itself also contributes to the decarbonisation objective: since 2020, vehicle production at the Porsche sites in Zuffenhausen and Leipzig has had a CO2-neutral balance sheet across the entire value chain and uses electricity generated via regenerative energy sources.

E-mobility is nothing new

The electric powertrain is embedded deep in the Porsche DNA.

Ferdinand Porsche, later the founder of the company of the same name, was fascinated by electricity even as a teenager. As early as 1893, the 18-year-old installed an electric lighting system in his parents’ house. In the same year Porsche joined Vereinigte Elektrizitäts-AG Béla Egger in Vienna. After four years there, he progressed from mechanic to head of the testing department. The first vehicles he designed also had electric drives — so in fact, the history of Porsche begins with the electric drive.

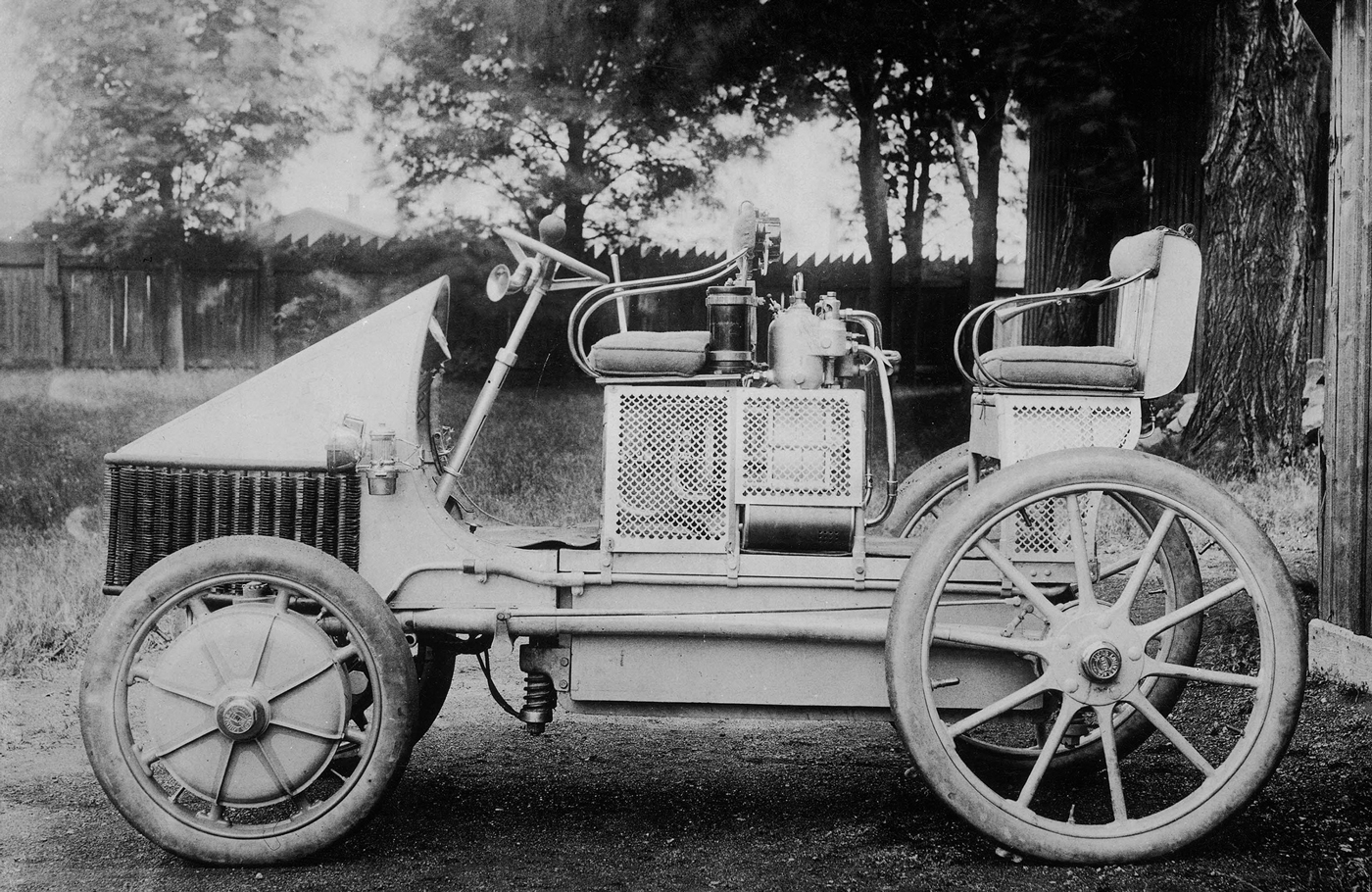

In 1898, Ferdinand Porsche designed the Egger-Lohner C.2 Phaeton. The vehicle was powered by an octagonal electric motor, and with three to five “Pferdestärke” (PS), or horsepower, it reached a top speed of 25km/h. In 1899, Porsche joined the carriage maker in Vienna: k.u.k. Hofwagenfabrik Ludwig Lohner & Co. There, he developed the electric wheel hub motor. In 1900, the first Lohner-Porsche Electromobile with this innovation was presented at the Expo in Paris. Offering 2 x 2.5PS, it reached a top speed of 37km/h. Lohner’s reason for a vehicle with an electric motor sounds as topical today as it did then, especially in relation to the era of mass motorisation: the air was “ruthlessly spoiled by the large number of petrol engines in use”.

Also in 1900, Porsche designed the world’s first functional hybrid car, the “Semper Vivus” (Latin for “always alive”). The technology, marketed as the Lohner-Porsche system, also had applications beyond the sphere of electric vehicles. Porsche extended the car’s range by not using a battery as an energy source, but instead using a combustion engine to drive a generator and thus supply the wheel hub with electrical energy. One year later, the production-ready version was born as the Lohner-Porsche “Mixte”.

However, the Lohner-Porsche also demonstrated why electric mobility has failed over the decades: despite its modest power output, the car weighed almost two tonnes. The lack of infrastructure and the short range put an end to electromobility for a long time.

The idea was resurrected more than 100 years later: with the development of lithium-ion batteries suitable for use in vehicles and evermore stringent legal requirements for pollutant and CO2 emissions, the focus turned once more to electric drive systems. With the Cayenne S Hybrid in 2010, Porsche paved the way for electromobility in the company.

Published by

Focus on Transport

focusmagsa