Demystifying demulsifier additives

Demystifying demulsifier additives

Regular oil analysis is crucial for detecting potential failures before they occur. STEVEN LUMLEY explores how demulsifier additives help combat water contamination in lubricants to ensure optimal performance and reduce wear in mechanical systems.

At WearCheck, we recommend regular analysis of engine oil and other fluids to ensure that all components are in good working order and that no failures are imminent.

Closely monitoring a lubricating system is a proven way to avoid unexpected breakdowns. One common source of trouble is water contamination, which can compromise lubrication performance and accelerate wear. To counteract this, demulsifier additives are used to disrupt the stability of water-in-oil emulsions, allowing the water to be separated for removal.

But what are demulsifier additives, and how can they be used for maximum benefit?

Demulsifiers

What are they? | Organic soaps and soaps of fatty acids, organic polymers. |

What do they do? | Encourage water to separate out of oil. |

How do they do it? | Break down the oil-water interface so that water droplets can coalesce and sink. |

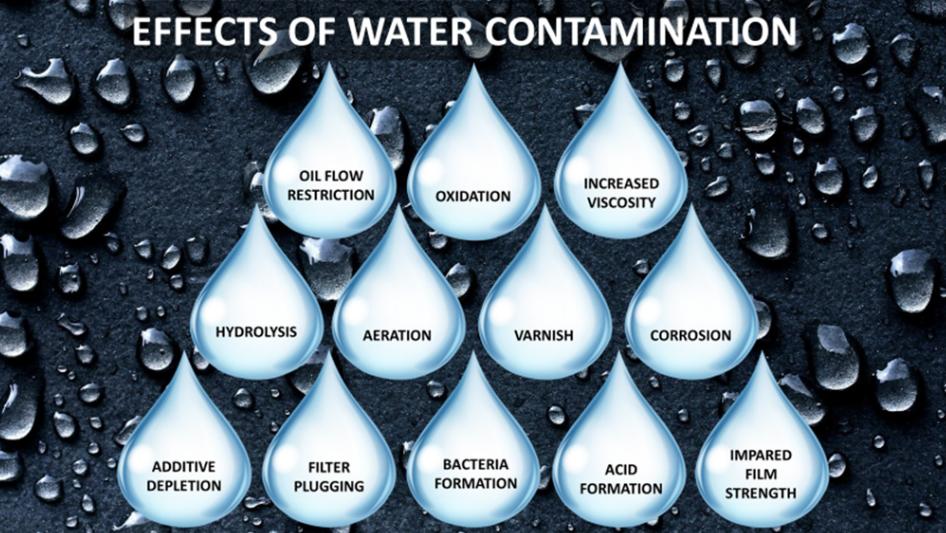

The effects of water contamination on oil and the lubricated system can be highly damaging. Water is one of the most destructive contaminants in almost all lubricants and applications. It attacks the base oil, depletes additives, and compromises the mechanical system being lubricated.

Water can accelerate oxidation, shortening the lubricant’s service life. It encourages sludge and varnish build-up and causes metal parts to rust and corrode. Water can also weaken the lubricant’s film strength, making components more vulnerable to wear. Additionally, it strips additives, impacting performance and reducing the lubricant’s ability to protect metal surfaces.

Many oils separate well enough from water naturally. However, some base oils and additives are prone to forming a stable emulsion when water is present. In such cases, a demulsifier additive is required.

Demulsifier additives prevent the formation of a stable oil-water mixture by changing the interfacial tension of the oil, allowing water to coalesce and separate more efficiently. This is especially important for lubricants exposed to steam or water, as it enables free water to settle out and be drained from reservoirs. Most engine, gear, hydraulic, and turbine lubricants contain this additive.

To be clear, demulsifier additives do not prevent water from entering the oil. Instead, they facilitate water separation, limiting its destructive effects.

An interesting fact about this lesser-known additive: the chemical compounds used to create demulsifier additives belong to the same group of chemicals that are used to form stable oil-water emulsions in metalworking fluids and fire-resistant fluids – but in much lower concentrations. That’s right, folks: the same compounds that demulsify can also emulsify when added in large enough quantities!

focusmagsa