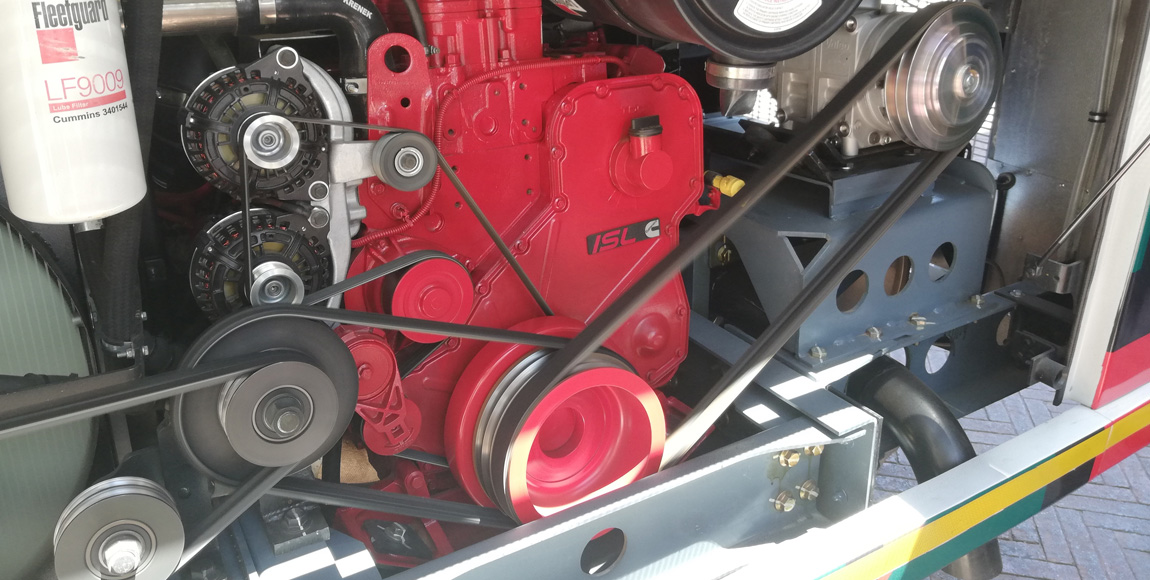

Cummins focuses on Africa

Engine manufacturer Cummins sets its sights on breaking production and service records in its centennial year – with African business opportunities listed as a primary focus

Cummins plans to cap its centennial year by setting a new record in 2019, manufacturing over 1,5-million engines and servicing about another 12-million in the global field. “What that means is that there are big opportunities for business, particularly in Africa,” says Christopher Judd, service engineering lead for Cummins Africa’s sub-Saharan region.

While competition is strong, Judd says Cummins aims to ensure the lowest total cost of ownership (TCO) for customers, hence a strategy that focuses on reducing repair cost, maintenance cost and time; reducing rebuild cost; and improving fuel economy.

“Engines we currently rebuild for the construction industry are upgraded using the latest technology, which allows for better efficiency while keeping the units within an affordable price range,” Judd says.

He says fuel contamination is probably the single-biggest maintenance issue in Africa, with consumers tending to think that, if fuel looks clean, it is. However, the reality is that contamination can be invisible to the naked eye.

“In terms of maintenance, the market has to be educated about contamination at the microscopic level. That extends to all the engine systems, not only fuel, but also air intake, cooling and lubrication systems,” he says.

Judd says that while engine users are becoming more aware of the importance of preventative maintenance in prolonging efficiency, they cannot monitor the engines they use on a 24-hour basis.

“That is not their core business. We can provide solutions that do just that, setting limits for service intervals, and recommending the lubricants, oils and coolants – all based on hard data. The drive for remote monitoring systems, and to improve our diagnostic support, is a major push for Cummins,” he says.

The Cummins Service Engineering team’s focus in Africa is to identify and prioritise any emerging product issues in the field. “We also support hard-to-diagnose complex troubleshooting, whereby we liaise closely with our factories in the United Kingdom, the United States, and China. Lastly, we also provide training and communication for any new product releases, including processes and tools,” he says.

The team supports all types of equipment and applications from on-highway vehicles to forklifts and reach stackers and – in the agricultural sector – tractors. However, mining remains a significant part of the company’s business.

“We are in the process of building a Master Rebuild Centre and Parts Distribution Centre in Morocco to service the mining industry in northern Africa. We are investing significantly in the mining space,” Judd reveals.

Looking to the future, he maintains that diesel as a primary fuel is going to be around for a long time. The technology will, in most cases, be more cost-effective than petrol, due to its efficiency.

However, Cummins also offers a large range of natural-gas engines and is fully set up to provide support in this regard. In addition, the company offers dual-fuel engines, which it claims is an ideal solution for customers in remote areas of Africa where they have an unreliable diesel supply.

Published by

Focus on Transport

focusmagsa